Chapter 10 - Evaporation PDF

| Title | Chapter 10 - Evaporation |

|---|---|

| Pages | 28 |

| File Size | 978.5 KB |

| File Type | |

| Total Downloads | 297 |

| Total Views | 788 |

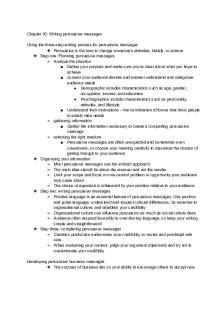

Summary

Chapter 10 Evaporation Instructor: Dr. Rami Jumah Department of Chemical Engineering Jordan University of Science and Technology Evaporation Chapter 8 (Geankoplis) Heat is added to a solution to vaporize the solvent, which is usually water. Chapter 16 (McCabe) Solvent vapor Feed (volatile solvent ...

Description

Chapter 10 Evaporation

Instructor: Dr. Rami Jumah Department of Chemical Engineering Jordan University of Science and Technology

Evaporation

Chapter 8 (Geankoplis) Chapter 16 (McCabe) Heat is added to a solution to vaporize the solvent, which is usually water. Solvent vapor

Feed (volatile solvent & non-volatile solute) Concentrated solution

Case of heat transfer to a boiling liquid. Vapor from a boiling liquid solution is removed and a more concentrated solution remains. Refers to the removal of water from an aqueous solution. Examples: - Concentration of fruit juice, milk or caustic soda - Production of high quality water from river/sea JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 1-2

Production of Milk Powder

Standardization to adjust the content of fat in milk

Heating to sterilize Falling-film evaporator

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Spray dryer to get milk powder Chapter 10-3

Processing Factors (1)Concentration - Dilute feed: viscosity , heat transfer coefficient, h also TBPsoln. ≈ TBPwater - Concentrated solution: , and h & TBPsoln. → (boiling point rise, BPR)

(2) Solubility - Concentration , solubility , crystal formed. - Solubility (normally) with temperature

(3) Temperature - Heat sensitive material degrade at higher temperature & prolonged heating. - Examples: foodstuffs, pharmaceuticals

(4) Scale deposition - Product decomposition & solubility decrease → deposition of solid materials on the heating surfaces : U → cleaning required JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 1-4

(5) Foaming/frothing - Caustic solutions, food solutions, fatty acid solutions form foam/froth during boiling. - Accompanies the vapor coming out of the evaporator and entrainment losses occur. (6) Pressure and Temperature - Pressure , boiling point . - Concentration , boiling point Boiling Point Rise (BPR) - Heat-sensitive material operate under vacuum → Tsolution ↓ A

q A ? U Tsteam Tsolution

(7) Material of construction Minimize corrosion. JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 1-5

Types of Evaporation Equipment

Horizontal tube type Vertical tube type Long tube vertical type Forced-circulation type Open kettle or pan Open-pan solar evaporator Falling-film-type evaporator Agitated-film evaporator

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 1-6

Effect of Processing Variables on Evaporator Operation (1) Feed Temperature (TF): - TF < TBP: some of latent heat of steam will be used to heat up the cold feed, only the rest of the latent heat of steam will be used to vaporize the feed. - If the feed is under pressure & TF > TBP, additional vaporization is obtained by flashing of feed. - Preheating the feed can reduce the size of the evaporator heat transfer area

(2) Evaporator Pressure (P1): - Desirable: large T A & cost .

q = U A T = UA (TS – T1) T1 = TBP

- T1 depends on P1 will T1 use vacuum pump (3) Steam Pressure (Ps): - Desirable: high steam pressure TS T A & cost - But high-pressure is costly optimum TS by overall economic balances JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 1-7

Boiling Point Rise of Solutions (BPR) - The concentration of the solution are high enough so that the cP and TBP are quite different from water - BPR can be predict from Duhring chart for each solution such as NaOH and sugar solution.

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-8

Enthalpy-concentration Charts of Solutions - For large heat of solution of the aqueous solution - To get values for hF and hL

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-9

Typical Heat Transfer Coefficients for Various Evaporators

Type of evaporator

U (W/m2.K)

Short-tube vertical, natural circulation

1100-2800

Horizontal-tube, natural circulation

1100-2800

Long-tube vertical, natural circulation

1100-4000

Long-tube vertical, forced circulation

2300-11000

Agitated film

JUST Department of Chemical Engineering

680-2300

ChE 362 Unit Operations

Chapter 10-10

Methods of Operation of Evaporators 1. Single-effect Evaporators - Used when the required capacity of operation is small and/or the cost of steam is cheap compared to the evaporator cost. - Is wasteful of energy since the latent heat of the vapor leaving is not used. - Solution in the evaporator is assumed to be completely mixed: (C1,

Vapor,V to condenser T1 , yV , HV

T1)product = (C1, T1)solution inside

- Equilibrium: vapor T = TBPsoln= T1 - P = P1 = vapor pressure of solution at T1

Feed, F TF , xF , hF.

T1

heat-exchanger tubes

Steam, S TS , HS

JUST Department of Chemical Engineering

P1

Condensate, S TS , hS Concentrated liquid, L T1 , xL , hL

ChE 362 Unit Operations

Chapter 1-11

2. Forward-feed Multiple-effect Evaporators

Used when the feed is hot or when the final concentrated product might be damaged at high temperatures T1 > T2 > T3,

P1 (atm.) > P2 > P3 (vac.), vapor T1

feed, TF

(1)

T1

C1 < C2 < C3,

vapor T2

vapor T3

(2)

to vacuum condenser

(3)

T3

T2

steam, TS

condensate concentrate from first effect.

JUST Department of Chemical Engineering

concentrate from second effect.

concentrated product

ChE 362 Unit Operations

Chapter 10-12

3. Backward-feed Multiple-effect Evaporators - Used when the feed is cold since a smaller amount of liquid must be heated to the high temps in the second and first effects - Used when the final concentrated product is highly viscous. The high temperature in the first effect reduce the viscosity and give reasonable heattransfer coefficient. T1 > T2 > T3,

P1 (atm.) > P2 > P3 (vac.), vapor T1 (1)

vapor T2 (2)

C1 > C2 > C3 vapor T3

to vacuum condenser

(3)

feed, TF steam, TS

T1

T2

T3 condensate

concentrated product JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-13

4. Parallel-feed Multiple-effect Evaporators - Involve the adding of fresh feed and the withdrawal of concentrated product from each effect - Used when the feed is almost saturated and solid crystals are the product e.g. evaporation of brine to make salt

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-14

Calculations Methods for Single-effect Evaporators CALCULATIONS

(1)

a) Vapor, V and liquid, L flowrates b) Heat transfer area, A c) Overall heat-transfer coefficient, U d) Fraction of solid content, xL

To calculate V & L and xL:

solve simultaneously total material balance & solute/solid balance. F=L+V F (xF) = L (xL) Vapor,V to condenser T1 , yV , HV

Feed, F TF , xF , hF.

P1

Steam, S

A

TS , HS

heat-exchanger tubes

Condensate, S TS , hS Concentrated liquid, L T1 , xL , hL

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-15

(2) To calculate A or U:

-

No boiling point rise and negligible heat of solution: 1. Calculate hF, hL, Hv and . where, = (HS – hs) hF = cPF(TF – Tref); hL = cPL(T1 – Tref) where, Tref = T1 cP = heat capacity (dilute as water) HV = latent heat at T1 2. Solve for S (energy balance): F hF + S = L hL + V HV 3. Solve for A and U: q = S = U A T = UA (TS – T1)

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-16

(3) To get BPR and the heat of solution:

1)

Calculate T1 = Tsat + BPR

2)

Get hF and hL from h-conc. charts (e.g., Figure 8.4-3)

3)

Get S & HV from steam tables for superheated vapor or HV = Hsat + 1.884 (BPR)

4)

Solve for S: F hF + S = L hL + V H V

5)

Solve for A and U: q = S = U A T = UA (TS – T1)

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-17

Example 8.4-1: Heat-Transfer Area in Single-Effect Evaporator A continuous single-effect evaporator concentrates 9072 kg/h of a 1.0 wt % salt solution entering at 311.0 K (37.8 ºC) to a final concentration of 1.5 wt %. The vapor space of the evaporator is at 101.325 kPa (1.0 atm abs) and the steam supplied is saturated at 143.3 kPa. The overall coefficient U = 1704 W/m2 .K.

Calculate the amounts of vapor and liquid product and the heattransfer area required. Assume that, since it its dilute, the solution has the same boiling point as water.

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-18

F = 9072 kg/h TF = 311 K xF = 0.01 hF.

V=? T1 , y V , HV P1 = 101.325 kPa

U = 1704 W/m2 T1 =? A = ? S , TS , HS PS = 143.3 kPa

S, TS , hS L=? T1 , hL xL = 0.015

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-19

Solution Total material balance: F = L + V 9072 = L + V Balance on the solute (solids) alone: F xF = L xL 9072 (0.01) = L (0.015)

L = 6048 kg/h of liquid

V = 3024 kg/h of vapor

Since it is assumed that the solution is dilute as water hF = cpF (TF – T1)

cpF = 4.14 kJ/kg. K

(Tref = T1)

hF = 4.14 (311.0 – 373.2) = -257.508 kJ/kg hL = cPL(T1 – Tref) = 0, since it is at T1 = Tref = 373.2 K From steam table (Appendix A.2-9, Geankoplis) Vapor (V) at P1 = 101.325 kPa: T1 = 373.2 K (100 ºC) & HV = = 2257 kJ/kg Sat. steam at PS = 143.3 kPa: TS = 383.2 K (110 ºC) & = 2230 kJ/kg JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-20

Substituting into heat balance equation: F hF + S = L hL + V H V 9072 (-257.508) + S (2230) = 6048 (0) + 3024 (2257) S = 4108 kg steam /h The heat q transferred through the heating surface area, A is q = S () = 4108 4108 kg/h (2230 kJ/kg) (1000 / 3600) = 2 544 000 W q = U A T = U A (TS – T1)

But

2 544 000 = 1704 A (383.2 – 373.2)

A = 149.3 m2

Steam or evaporator economy = V/S = 3024 kg/h vapor / 4108 kg steam /h = 0.736

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-21

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-22

Example 8.4-3: Evaporation of an NaOH Solution An evaporator is used to concentrate 4536 kg/h of a 20 % solution of NaOH in water entering at 60 ºC to a product of 50 % solid. The pressure of the saturated steam used is 172.4 kPa and the pressure in the vapor space of the evaporator is 11.7 kPa. The overall heat-transfer coefficient is 1560 W/m2.K. Calculate the steam used, the steam economy in (kg vaporized/kg steam) used, and the heating surface area in m2. F = 4536 kg/h TF = 60 ºC xF = 0.2 hF.

V, T1 , yV , HV P1 = 11.7 kPa U = 1560 W/m2 T1 A= ?

S=? TS , HS PS = 172.4 kPa L, T1 , hL xL = 0.5 JUST Department of Chemical Engineering

S, TS , hS

ChE 362 Unit Operations

Chapter 10-23

Solution Total material balance: F = L + V 4536 = L + V Balance on the solute (solids) alone: F xF = L xL 4536 (0.2) = L (0.5) L = 1814 kg/h of liquid

V = 2722 kg/h of vapor

Determine T1 = Tsat + BPR of the 50 % concentrate product: First obtain Tsat of pure water from steam table at 11.7 kPa Tsat = 48.9 ºC

From Duhring chart (Fig. 8.4-2), for a Tsat = 48.9 ºC and 50 % NaOH : the boiling point of the solution is T1 = 89.5 ºC

BPR = T1 - Tsat = 89.5-48.9 = 40.6 ºC

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-24

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-25

From the enthalpy-concentration chart (Fig.8.4-3): At TF = 60 ºC

and

xF = 0.2

At T1 = 89.5 ºC and

xL = 0.5

JUST Department of Chemical Engineering

ChE 362 Unit Operations

hF = 214 kJ/kg hL = 505 kJ/kg

Chapter 10-26

For saturated steam at 172.4 kPa (from steam table): TS = 115.6 ºC

and

= 2214 kJ/kg.

To get HV for superheated vapor: first obtain the enthalpy at Tsat = 48.9 ºC and P1 = 11.7 kPa:

Hsat = 2590 kJ/kg. Then using heat capacity of 1.884 kJ/kg.K for superheated steam. HV = Hsat + cP (BPR) = 2590 + 1.884 (40.6) = 2667 kJ/kg Or: from superheated steam table at T1 = 89.5 ºC and P1 = 11.7 kPa HV = 2667 kJ/kg Substituting into heat balance equation and solving for S, F hF + S = L hL + V H V 4535 (214) + S (2214) = 1814 (505) + 2722 (2667)

S = 3255 kg steam /h. JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-27

The heat q transferred through the heating surface area, A is q = S () q = 3255 (2214) (1000 / 3600) = 2 002 000 W

But

q = U A T = U A (TS – T1) 2 002 000 = 1560 A (115.6 – 89.5)

A = 49.2 m2.

Steam or evaporator economy = V/S = 2722 kg/h vapor / 3255 kg steam /h = 0.836

JUST Department of Chemical Engineering

ChE 362 Unit Operations

Chapter 10-28...

Similar Free PDFs

Chapter 10 - Evaporation

- 28 Pages

Evaporation pan - JGGHH

- 3 Pages

Chapter 10 quiz #10

- 3 Pages

Notes 10 - Chapter 10

- 5 Pages

Chapter-10

- 19 Pages

Chapter 10

- 5 Pages

Chapter 10

- 14 Pages

Chapter 10

- 111 Pages

Chapter 10

- 16 Pages

Chapter 10

- 47 Pages

Chapter 10

- 4 Pages

Chapter 10

- 5 Pages

Chapter 10

- 6 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu