CHE241 - Lab Report Flowmeter Measuremen PDF

| Title | CHE241 - Lab Report Flowmeter Measuremen |

|---|---|

| Author | Zain Chughtai |

| Course | Fluid Mechanics |

| Institution | INTI International University |

| Pages | 36 |

| File Size | 1 MB |

| File Type | |

| Total Downloads | 14 |

| Total Views | 149 |

Summary

fluid mech...

Description

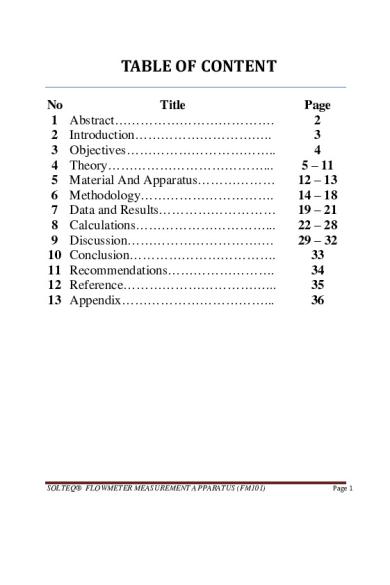

TABLE OF CONTENT No 1 2 3 4 5 6 7 8 9 10 11 12 13

Title Abstract………………………………. Introduction………………………….. Objectives…………………………….. Theory………………………………... Material And Apparatus……………… Methodology…………………………. Data and Results……………………… Calculations…………………………... Discussion……………………………. Conclusion……………………………. Recommendations……………………. Reference……………………………... Appendix……………………………...

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 2 3 4 5 – 11 12 – 13 14 – 18 19 – 21 22 – 28 29 – 32 33 34 35 36

Page 1

1.0

ABSTRACT SOLTEQ® Flowmeter Measurement Apparatus (Model: FM101) is designed to

measure a flow of an incompressible fluid. From this experiment, we will obtain the flow rate measurement with comparison of pressure drop by utilizing three basic types of flow measuring techniques; ratometer, venture meter and orifice meter. Meanwhile, the loss coefficient can be determined when fluid flows through a 90◦ elbow by measuring flow rate on manometers. Actual flow rates for the water is determined by using a constant volume of 10L and the time taken for the water to reach until 10L for each experiment. We could compare the flow rates of the flowmeter based on the results we get from the graph. It shows that venturi meter is more accurate compare to orifice meter which the flow rates of venturi meter is closer to the actual value of the flow rates. On the whole, our experiment was successfully done because we has achieved the objective of the experiment.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 2

2.0 INTRODUCTION SOLTEQ® Flowmeter Measurement Apparatus (Model: FM101) apparatus is designed to operate together with a basic hydraulic bench or a water supply. This enables students to familiarize themselves with typical methods of flow measurement of an incompressible fluid. This apparatus will allow students to compare between different types of flow measurement devices, namely by using a venturi device, orifice device and rotameter. The data obtained can be further used to compare against measurement obtained from the hydraulics bench. Other feature of the flow apparatus includes a 90 degree elbow with pressure tappings. This feature allows students to calculate the total head loss and loss coefficient when fluid flows through the 90 degrees elbow. In short, the apparatus allows the following experiment to be carried out: a) A comparison of flow measurement using venturi, orifice, rotameter and bench. b) Determination of total head loss and loss coefficient of fluid flow through a 90 degree elbow.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 3

3.0

OBJECTIVE Based on this experiment, the main objectives of this experiment is to obtain the flow rate

measurement with comparison of pressure drop by utilizing three basic types of flow measuring technique which are rotameter, venturi meter and orifice meter. Besides, to investigate the loss coefficient of fluid flow through 90 degree elbow. Other than that, to determine the total head loss of fluid flow. Then, we need to learn how to plot graph of ΔH against . Last but not least, to verify experimentally the validity of Bernoulli’s equation for fluid flow.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 4

4.0 THEORY Rotameter The rotameter is a flow meter in which a rotating free float is the indicating element. Basically, a rotameter consists of a transparent tapered vertical tube through which fluid flow upward. Within the tube is placed a freely suspended “float” of pump-bob shape. When there is no flow, the float rests on a stop at the bottom end. As flow commences, the float rises until upward and buoyancy forces on it are balanced by its weight. The float rises only a short distance if the rate of flow is small, and vice versa. The points of equilibrium can be noted as a function of flow rate. With a well-calibrated marked glass tube, the level of the float becomes a direct measure of flow rate.

Figure 1 Rotameter

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 5

Venturi Meter

Figure 2 Venturi Meter The venturi meter consists of a venturi tube and a suitable differential pressure gauge. The venturi tube has a converging portion, a throat and a diverging portion as shown in the figure below. The function of the converging portion is to increase the velocity of the fluid and lower its static pressure. A pressure difference between inlet and throat is thus developed, where pressure difference is correlated with the rate of discharge. The diverging cone serves to change the area of the stream back to the entrance area and convert velocity head into pressure head. Assume incompressible flow and no frictional losses, from Bernoulli’s Equation

P1

V12 P V2 Z1 2 2 Z 2 ................................................................ (1) 2g 2g

Use of the continuity Equation Q = A1V1 = A2V2, equation (1) becomes

P1 P2

V2 A Z 1 Z 2 2 1 2 2g A1

2

...................................................... (2)

Ideal A2 2 Q A2V2 A2 1 A1

1

2

P1 P2 Z 1 Z 2 2g

1

2

....................... (3)

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 6

However, in the case of real fluid flow, the flow rate will be expected to be less than that given by equation (2) because of frictional effects and consequent head loss between inlet and throat. In metering practice, this non-ideality is accounted by insertion of an experimentally determined coefficient, Cd,termed as the coefficient of discharge. With Z1 = Z2 , equation (3) becomes A 2 Actual Q Cd A2 1 2 A1

1

2

P1 P2 2g

1 2

............................ (4)

Hence, 2 A q C d At 1 t A

1 2

P1 P2 2g

1

2

Where, Cd D2 D1 At A g ρ P1 P2

= = = = = = = = =

Coefficient of discharge (0.98) Throat diameter = 16 mm Inlet diameter = 26 mm Throat area = 2.011 x 10-4 m2 Inlet area = 5.309 x 10-4 m2 9.81 m/s2 Density of water = 1000 kg/m3 Inlet pressure (Pa) Throat pressure (Pa)

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 7

Orifice Meter The orifice for use as a metering device in a pipeline consists of a concentric square-edged circular hole in a thin plate, which is clamped between the flanges of the pipe as shown in the figure below.

Figure 3 Orifice Meter Pressure connections for attaching separate pressure gauges are made at holes in the pipe walls on both side of the orifice plate. The downstream pressure tap is placed at the minimum pressure position, which is assumed to be at the vena contracta. The centre of the inlet pressure tap is located between one-half and two pipe diameters from the upstream side of the orifice plate, usually a distance of one pipe diameter is employed. Equation (4) for the venturi meter can also be applied to the orifice meter where A2 2 Actual Q Cd A2 1 A1

1

2

P1 P2 2g

1 2

............................... (6)

The coefficient of discharge, Cd in the case of the orifice meter will be different from that for the case of a venturi meter. A 2 q C d At 1 t A

1 2

2 g h7 h8 1 2

Where, Cd D7 D8 At A (h7 – h8)

= = = = = =

Coefficient of discharge (0.63) Orifice diameter = 16 mm Orifice upstream diameter = 26 mm Orifice area = 2.011 x 10-4 m2 Orifice upstream area = 5.309 x 10-4 m2 Pressure difference across orifice (m)

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 8

90゜ ゜ELBOW Figure below shows fluid flowing in a pipeline where there is some pipe fitting such as bend or valve, and change in pipe diameter. Included in the figure is the variation of piezometric head along the pipe run, as would be shown by numerous pressure tappings at the pipe wall.

Figure 4 Piezometric head along the pipeline If the upstream and downstream lines of linear friction gradient are extrapolated to the plane of fitting, a loss of piezometric head, h, due to the fitting is found. By introducing the velocity heads in the upstream and downstream runs of pipe, total head loss, H can be determined in which H h

V12 V2 2 ............................................................... (8) 2g 2 g

Energy losses are proportional to the velocity head of the fluid as it flows around an elbow, through an enlargement or contraction of the flow section, or through a valve. Experimental values for energy losses are usually expressed in terms of a dimensionless loss coefficient K, where K

H H .............................................................. (9) or 2 2 V2 V1 2g 2g

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 9

For results of better accuracy, long sections of straight pipe are required to establish with certainty the relative positions of the linear sections of the piezometric lines. However, in a compact apparatus as described in this manual, only two piezometers are used, one placed upstream and the other downstream of the fitting, at sufficient distances as to avoid severe disturbances. These piezometers measure the piezometric head loss, h’ between the tapping. Thus ∆h = ∆h’ - ∆hf ....................................................................... (10)

L V2 Where ∆hf = 4 f ( )( ) D 2g

Δhf

= friction head loss which would be incurred in fully developed flow along the run of pipe between the piezometer tappings. = friction factor = distance between the piezometer, measured along the pipe center line = pipe diameter = average velocity of fluid flow in pipe

f L D V

The friction head loss is estimated by choosing a suitable value of friction factor, f for fully developed flow along a smooth pipe. The method used in this manual to determine the friction factor is the Prandtl equation 1 4 log Re f

f 0.4 ................................................................. (11)

Typical values derived from this equation are tabulated in the table below: Re, x 104 0.5

1.0

1.5

2.0

2.5

3.0

3.5

F, x 10-3

7.73

6.96

6.48

6.14

5.88

5.67

9.27

In determination of the fraction factor, f, it is sufficient to establish the value of f at just one typical flow rate, as about the middle of the range of measurement due to the fact that f varies only slowly with Re, and the friction loss is generally fairly small in relation to the measured value of ∆h’.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 10

Characteristic of flow through elbow and at changes in diameter 90゜ ゜ Elbow Figure below shows flow round a 90゜elbow which has a constant circular cross section.

Figure 5 90゜ elbow

The value of loss coefficient K is dependent on the ratio of the bend radius, R to the pipe inside diameter D. As this ratio increase, the value of K will fall and vice versa.

H = KV2 / 2g …………………………………………..…… (12)

Where, K

= Coefficient of losses

V

= Velocity of flow

g

= 9.81 m/s2

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 11

5.0 MATERIAL AND APPARATUS Material 1) Water

Apparatus 1) Flowmeter Measurement Apparatus (Model: FM 101)

5

1 6

2 3 4

7

9

8

1) Manometer tubes

6) Rotameter

2) Discharge Valves

7) 90⁰ Elbow

3) Water Outlet

8) Orifice

4) Water Supply

9) Venturi

5) Staddle Valve

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 12

2) Hydraulic bench – To allow water flow by time volume collection to be measured.

3) Stop watch - determine the flowrate of the water

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 13

6.0 METHODOLOGY 6.1

General Start-up Procedures

The Flowmeter Measurement Apparatus (Model: FM 101) is supplied ready for use and only requires connection to the Hydraulic Bench (Model: FM 110) as follows: a) The apparatus were placed on top of a suitable hydraulic bench. b) The apparatus was levelled on the bench top. c) The hydraulic coupling was connected to the outlet supply of the hydraulic bench. d) The discharge connects of the flow apparatus hose were connected to the collection tank of the hydraulic bench. e) The apparatus was ready to operate.

Starting up the Apparatus: 1) The flow control valve of hydraulic bench was fully closed and the discharge valve was fully open. 2) The discharge hose were ensured that it was properly directed to volumetric tank of fibreglass before starting up system. Then the volumetric tank drain valve is ensured left OPEN to allowed flow discharge back into sump tank. 3) Once step (b) is confirmed start up the pump supply from hydraulic bench. The bench valve slowly opened. At this time, water flowing from hydraulic bench through to the flow apparatus, and was discharge through into the volumetric tank of hydraulic bench and then were drained back into sump tank of hydraulic bench. 4) Proceed to fully open the flow control valve. When the flow in the pipe is steady and there is no trapped bubble, start to close the bench valve to reduce the flow to the maximum measurable flow rate. 5) The water level in the manometer board will started to display different level of water heights. (If the water level in the manometer board were too high where it is out of visible point, the water level should be adjusted by using the staddle valve. With the maximum measurable flow rate, retain maximum readings on manometer).

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 14

6) Then, the flow was slowly reduced by controlling the flow discharge valve of apparatus and this discharge valve were closed totally. 7) The water level in the manometer board started to level into a straight level. This level can be at the lower or at the higher end of the manometer board range. (At this time, the pump from the hydraulic bench was, still supplying water at a certain pressure in the system). 8) The “Trapped Bubbles” in the glass tube or plastic transfer tube was checked. Trapped bubbles must be removed from the system for better accuracy, this can be done by slowly “press the plastic tube to push the bubbles up or lightly “tab” the glass tube to releasing the bubbles upwards.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 15

Note: If above methods fail, “flush” the system by “bleeding” were used to free air out. All that is required is the use of a small object such as pen or screw driver, to depress the staddle valve, found at the top right side of manometer board. Staddle valve were depressed lightly to allow fluid and trapped air to escape out. (Take care it wet self or the premise). Allow sufficient time for bleeding until all bubbles escape.

Once all bubbles have been “bleed”, start to reduce the water supply by manipulating BOTH control valves, the flow apparatus discharge valve were reducing and then the hydraulic bench valve in alternate motion, bringing down the DATUM level of the water in the manometer board.

(i)

At this point the experiment may start proper.

(j)

Data obtained from tubes that were used are: Probe A and C for venturi calculation Probe G and H for orifice calculation Probe I and J for 90 degree elbow calculation All other probe readings was for viewing of pressure curve ONLY.

(k)

With above guide, the water level of each probe at a certain flow was recorded. With the height difference, formulas provided were used to calculate. The results obtained against rotameter and hydraulic bench was verified for experiment of flow measurement comparison.

(l)

The experiment was completed with other flow rates.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 16

6.2

Demonstration of the operation and characteristic of three different basic types of flowmeter

Procedures:

1) The apparatus was placed on bench, inlet pipe were connected to bench supply and outlet pipe into volumetric tank. 2) As the bench valve fully closed and as the discharge valve fully opened, start up the pump supply from hydraulic bench. 3) The bench valve, were slowly opened until it was fully opened. 4) After the flows in the pipe were steady and there are certainly no trapped bubble, the bench valve started to close to reduce the flow to the maximum measurable flow rate. 5) The water level in the manometer board was adjusted, by using the air bleed screw. The maximum readings on manometers with the maximum measurable flow rate were recorded. 6) The readings on manometers (A - J), rotameter and measured flow rate were recorded. 7) Step 6 is repeated for different flow rates. The flow rates were adjusted by utilizing both bench valve and discharge valve. 8) To demonstrate similar flow rates at different system static pressures, bench and flow control valve were adjusted together. Manometer levels were adjusted as required.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 17

6.3

Determination of the loss coefficient when fluid flows through a 90 degree elbow

Procedures:

1) The apparatus was placed on bench, inlet pipe were connected to bench supply and outlet pipe into volumetric tank. 2) As the bench valve fully closed and as the discharge valve fully opened, start up the pump supply from hydraulic bench. 3) The bench valve, were slowly opened until it was fully opened. 4) After the flows in the pipe were steady and there are certainly no trapped bubble, the bench valve started to close to reduce the flow to the maximum measurable flow rate. 5) The water level in the manometer board was adjusted, by using the air bleed screw. The maximum readings on manometers with the maximum measurable flow rate were recorded. 6) The readings on manometers (I and J) were recorded and the flow rate were calculated. 7) Steps 6 were repeated for different flow rates. The flow rates were adjusted by utilizing both bench valve and discharge valve. 8) The tables of data were completed. 9) The graph of H against VS2 / 2g for 90 degree elbow were plotted to determine the coefficient of losses.

6.4

General Shut-down Procedures

1) The water supply valve and venturi discharge valve was closed. 2) The water supply pump was turned off. 3) The water from the unit were drain off after the experiment was finished.

SOLTEQ® FLOWMETER MEASUREMENT APPARATUS (FM101)

Page 18

7.0 DATA AND RESULTS Demonstration Of The Operation And Characteristis of Three Different Basic Types of Flowmeter Venturi Meter Exp...

Similar Free PDFs

LAB 5 - Lab report

- 4 Pages

Lab 8 - lab report

- 6 Pages

TLC Lab Lab Report

- 4 Pages

Lemonade Lab - Lab report

- 4 Pages

Post Lab - lab report

- 2 Pages

TLC lab - Lab report

- 3 Pages

Lab 8 - lab report

- 3 Pages

Lab 6 - Lab Report

- 6 Pages

Lab Report 5 - lab

- 5 Pages

Planaria lab - lab report

- 6 Pages

Acceleration lab - lab report

- 3 Pages

Lab 1 - lab report

- 3 Pages

Enthalpy lab report - Lab

- 4 Pages

Lab Report 9 - lab

- 6 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu