Lab 8 multisynthesis of Dimethyl-3,4,5,6-tetraphenylphthalate PDF

| Title | Lab 8 multisynthesis of Dimethyl-3,4,5,6-tetraphenylphthalate |

|---|---|

| Course | Organic Chemistry Laboratory Ii |

| Institution | Hunter College CUNY |

| Pages | 12 |

| File Size | 786.8 KB |

| File Type | |

| Total Downloads | 20 |

| Total Views | 129 |

Summary

Lab 8 multisynthesis of Dimethyl-3,4,5,6-tetraphenylphthalate...

Description

4 / 2 6/ 2 0 La b8 : Multistep Synthesis of Dimethyl-3,4,5,6-tetraphenylphthalate I nt r oduc t i o n: Th r e es t e p sa r er e q u i r e dt os y n t h e s i z eDimethyl-3,4,5,6-tetraphenylphthalate. In the first step, an oxidation reaction occurs synthesizing benzil from benzoin. Benzil is formed through oxidation of benzoin with nitric acid and hazardous NO2 gas is expelled, emphasizing the importance of doing this synthesis under the fume hood. After Benzil is synthesized, a basecatalyzed aldol condensation occurs with Benzil and diphenyl acetone to form tetraphenyl cyclopentadienone. In this reaction, an aldol addition occurs first with a proton transfer with an alpha proton next to the ketone forming an enolate ion. The enolate ion formed from diphenyl acetone attacks benzil and then a series of proton transfers occur to obtain aldol product of tetraphenyl cyclopentadienone. Lastly a Diels Alder reaction is performed with tetraphenyl cyclopentadienone, dimethylacetylenedicarboxylate, and o-dichlorobenzene to form Dimethyl3,4,5,6-tetraphenylphthalate. This Diels alder reaction is concerted and allows the diene of tetraphenyl cyclopentadienone to react with dienophile dimethylacetylenedicarboxylate to create new carbon-carbon bonds which allow a more stable benzene product of Dimethyl-3,4,5,6tetraphenylphthalate to form. A s-cis conjugated diene is required for a [ 4+2] cycloaddition of alkyne dienophile. Melting points and percent yields were obtained at each step to assess purity and to make sure a good amount of product is obtained.

Me t ho dsa ndMa t e r i a l s : Th i se x p e r i me n twa sd i v i de di n t ot h r e ed a y s . Be nz i lp r o d u c twa so b t a i n e do nt h efir s t da y , a n dus e da sr e a c t a n tont hes e c o n dd a yt oo b t a i np r o du c ttetraphenyl cyclopentadienone and tetraphenyl cyclopentadienone was used as a reactant on the third day to form final product of Dimethyl-3,4,5,6-tetraphenylphthalate. Percent yields and melting points of each product obtained was measured. This multistep synthesis was performed as described in the Chem 225 Lab manual pp 37-38.

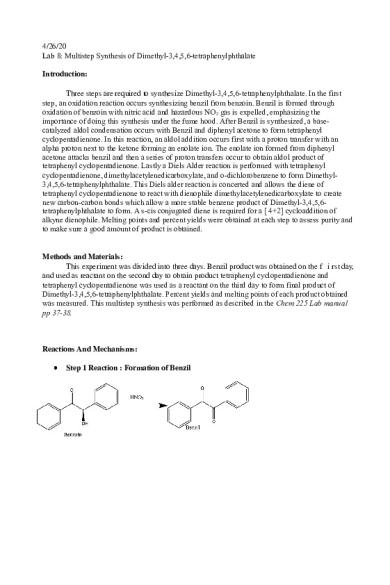

Re a c t i o nsAndMe c ha ni s ms :

St e p1Re a c t i o n:Fo r ma t i o no fBe nz i l

St e p1Me c ha ni s m:

St e p2Re a c t i o n:Fo r ma t i o no ftetraphenycyclopentadienone

Me c ha ni s m:

St e p3Re ac t i o n:Fo r ma t i o no fDimethyl-3,4,5,6-tetraphenylphthalate

Me c ha ni s m:

Re s ul ta ndObs e r v a t i o ns : St e p1 :Fo r ma t i o no fBe nz i l : Ye l l o wc r ys t a l so bt a i ne da sbe nz i lpr o duc t St a r t a mo u n to fBe n z o i nu s e d:5 . 0 go r0 . 0 2 3 5mo l s Fi na la mo u nto fBe nz i lo b t a i n e d:3 . 3 2 g

4. 1℃ Me a s u r e dme l t i n gpo i n to fb e n z i l :93 . 8 ℃ –9 Li t e r a t u r eme l t i n gpo i n to fb e n z i l :94 ℃ –9 5℃ ( Si g maAl dr i c h) St e p2 :For ma t i o no ftetraphenyl cyclopentadienone Dar kpur pl e /g l i t t e rl i kec r y s t al so bt a i ne dastetraphenyl cyclopentadienone product St a r t a mo u n to fBenzil u s e d :2 . 1 go r0 . 0 1mo l s Fi na la mo u nto ftetraphenyl cyclopentadienone o b t a i ne d :1 . 7 0g 22 4℃ Me a s u r e dme l t i n gpo i n to ftetraphenyl cyclopentadienone:2 2 0℃ – 2 0℃ ( Si g maAl dr i c h) Li t e r a t u r eme l t i n gpo i n to ftetraphenyl cyclopentadienone:2 1 7 ℃ –2 St e p3 :For ma t i o no fdimethyl-3,4,5,6-tetraphenylphthalate Li ghty e l l o w,a l mo s twhi t ec r y s t a l sf o r me dasdimethyl-3,4,5,6-tetraphenylphthalate St a r t a mo u n to ftetraphenyl cyclopentadienone u s e d :0 . 5 0go r0 . 0 0 1 3mo l Fi na la mo u nto fDimethyl-3,4,5,6-tetraphenylphthalate o b t a i n e d :0 . 4 7g Me a s u r e dme l t i n gpo i n to fdimethyl-3,4,5,6-tetraphenylphthalate:2 6 0℃ Li t e r a t u r eme l t i n gpo i n to fdimethyl-3,4,5,6-tetraphenylphthalate:2 5 8℃

– 2 65 ℃ –2 5 9℃

Tr e a t me nto fRe s ul t s :

%y i e l d=( Ac t ua ly i e l d/t he or e t i c a lyi e l d)x1 0 0

St e p1 :Fo r ma t i o no fBe nz i l :

Theoretical yield of Benzil product:

0.0235 mol Benzoin ( 210.23 g benzil 1 mol ¿

1 mol benzil )= 0.0235 mol benzil 1 mol benzoin

)(0.0235 mol benzil) = 4.94g of theoretical benzil product

%y i e l d=( 3 . 3 2g/4 . 94 )x10 0=6 7 . 2 % St e p2 :For ma t i o no ftetraphenyl cyclopentadienone

Theoretical yield of tetraphenyl cyclopentadienone product:

1mol benzil 0.01 mol Benzil ( 1 mol C 29 H 20 O )= 0.01 mol tetraphenyl cyclopentadienone ( ¿ ¿ C 29 H 20 O ¿

384.478 g C 29 H 20O )(0.01 mol C 29 H 20 O ) = 3.84g of theoretical tetraphenyl 1mol ¿ cyclopentadienone product

%y i e l d=( 1 . 7 0g/3 . 8 4 g )x1 0 0=4 4 . 3 %( di s c us sl o wy i e l db/ cduet ov a c uum fil t e r a t i o n e r r or , s o mepr o duc twa sdi s c a r de d.

St e p3 :For ma t i o no fdimethyl-3,4,5,6-tetraphenylphthalate

Theoretical yield of dimethyl-3,4,5,6-tetraphenylphthalate product:

1 mol C 29 H 20 O 0.0013 mol C29H20O ( 1 mol C 34 H 26 O 4 )= 0.0013 mol dimethyl-3,4,5,6¿ ¿ tetraphenylphthalate ( C 34 H 26 O ¿

498.6 g C 34 H 26 O 4 )(0.0013 mol C 34 H 26 O ) = 0.65g of theoretical dimethyl-3,4,5,61mol ¿ tetraphenylphthalate product

%y i e l d=( 0 . 4 7 g/0. 6 5 g )x1 0 0=7 2 . 3 0 g

HNMRsa ndCNMRs:

Di s c us s i ona ndCo nc l us i o n: Ov e r a l l ,t h emu l t i s t e ps y n t h e s i swa sas u c c e s sa n ddimethyl-3,4,5,6-tetraphenylphthalate was obtained as the product successfully. In step 1, benzil was synthesized, and the crystals that formed after recrystallization and vacuum filtration were bright yellow. The amount of benzil obtained was 3.32g while the theoretical amount that should’ve been obtained was 5g. This gave a percent yield of 67.2%. The percent yield could have been lowered due to errors that have occurred during this step of the experiment. For example, when drying and washing the product with methanol, the stirring rod had wet product stuck onto it that was wiped away. Also, when transferring the crystals to vacuum dry, some excess was left over and couldn’t be recovered in the flask. All of these could have been possible reasons as to why the percent yield was low. s9 3. 8 ℃ – Furthermore, in step 1, the experimental melting point range of benzil obtained wa l et h el i t e r a t u r ev a l u ef o un donSi g ma Al d r i c hg a v ear a n g eo f9 4 ℃ –9 5℃ . 9 4 . 1 ℃ whi Th ee x p e r i me n t a lme l t i n gp o i n th a sav e r yn a r r o wr a n g ea n di sv e r yc l o s et ot h el i t e r a t ur eme l t i n g p o i ntr a ng e , s i g n i f y i n gt h a tt h ebe nz i lp r o d u c tt h a twa so b t a i n e dwa sv e r yp u r ea n dl a c k e da n y i mpu r i t i e s . I ns t e p2 , t h ebe n z i lo b t a i n e df r om s t e p1wa sr e a c t e dwi t hd i p h e n y la c e t o net of o r m t e t r a p he n y lc y c l op e n t a d i e n o n e . Th ea c t u a le x p e r i me nt a lv a l u eofp r o du c to b t a i ne dwa s1 . 7 0g r a ms wh i l et h ea c t u a lc a l c ul a t e dv a l ue , a ss e e na b o v ei nt r e a t me nto fr e s u l t s , wa s3 . 84g r a ms . Th ep e r c e n t y i e l do bt a i ne dwa s44 . 3 %. Th ep e r c e n tyi e l dwa ss ol o wa l s od u et oa ne r r o rt h a twa sma d e .Wh e n v a c u u mfil t e r i n gt h ep r o d u c t , t h ec o r kt h a twa su s e db e t we e nt h eBu c h n e rf u n n e la n dt h efla s kwa s n ’ t s e a l e dp r o p e r l ya n ds o mep r od u c te n d e dupb e i n gd r a i n e di n t ot h efla s k .Th ep r o d u c tt h a tr e ma i ne d i nt h efla s kwa sr e fil t e r e da swe l lb u ts o mepr o d u c tr e ma i n e da tt h eb ot t o mo ft h efla s k . Af t e rt h e p r o d u c twa sdr y , i t ’ swa sd i ffic u l tt or e c o v e re v e r yl a s t s o l i dc r y s t a lf r o mt heBuc h n e rf u nn e lo n t ot h e s c a l es os o mep r o d u c tt h a t ’ sha r dt os c r a p eo ffe n d e du pb e i n gwa s h e da wa y . Du et ot h e s er e a s o n s t h ea c t u a ly i e l do ft e t r a p h e n y lc y c l o p e n t a d i e n o newa sl o wb u te n o u g hwa so b t a i n e df o ru s a g ei ns t e p 3 . Th eme l t i n gp o i n to ft e t r a p h e n y lc y c l o pe n t a d i e n onep r o d u c to b t a i ne dwa sme a s u r e du s i n gt h e 2 2 4℃ , wh i l et h el i t e r a t u r ev a l u ewa s21 7 Me l Te mpa p pa r a t usa ndr e c o r d e da s2 2 0℃ – ℃ –22 0℃ ( Si g ma Al d r i c h ) . Thee x p e r i me n t a ll i t e r a t u r ev a l u ewa ss l i g h t l ymo r eb r o a da n d s l i g ht l yh i g h e rt ha nt h el i t e r a t u r ev a l u e ,s i g ni f y i n gt h ep o s s i b i l i t yo ft h ep r e s e n c eo fs o mei mp u r i t y . Ac ommo ns o u r c eo fe r r o rwi t hme l t i n gp o i n tc o u l dha v eb e e nt ur ni n gt h en o bo ft h ema c h i n et o o q ui c kl yy i e l d i n gi n a c c u r a t er e a di n g sb u tf o ra l lt hr e eme a s u r e me nt s ,t het e mp e r a t u r ewa ss l o wl y i n c r e a s e d . Fo rs t e p3, t h et e t r a p h e n y lc y c l o p e n t a d i e n o n er e a c t e dwi t hdimethylacetylenedicarboxylate to form dimethyl-3,4,5,6-tetraphenylphthalate. The actual amount of dimethyl-3,4,5,6tetraphenylphthalate product obtained was 0.47g and the theoretical amount of product calculated was 0.65g. The percent yield was 72.3%. This percent yield could have also been lowered by errors that have occurred as explained above. The experimental melting point of dimethyl-3,4,5,62 6 2 ℃ wh i l et hel i t e r a t u r eme l t i n gp o i n t tetraphenylphthalate product was 2 5 9 . 8℃ – 5 9 ℃ .Thee x p e r i me n t a lme l t i n gp o i n twa s o b t a i n e df r o ms i g maAl d r i c hwa s2 5 8 ℃ –2 s l i g ht l yh i g h e rt ha nt h el i t e r a t u r eme l t i n gp o i n tbu ts t i l lb o t hr a n g e sa r ev e r yc l os et oe a c hot h e r s i g n i f y i ngt ha tt h ep r o d uc tf or me dwa ss t i l lp u r ee no u g h .

1. Benzil reacts with 1,2 diaminobenzene to give a compound with molecular formula C20H14N2. Suggest a structure for this compound and write a reaction mechanism to show how it is formed.

2. A driving force for the reaction in step 3 is the formation of carbon monoxide, a stable compound. How else can stability be used to explain the ease of this reaction. Th ea r o ma t i cr i n gt h a ti sr e s on a nc es t a b i l i z e di sf o r me di nt h i sr e a c t i o ni st h a ti smo r ef a v o r e dd u et o i t sgr e a t e rs t a b i l i t y . Si n c ec a r b o nmo n o xi d ei se x pe l l e d ,t h er e a c t i o nb e c o me si r r e v e r s i b l e .

Re f e r e n c e s : h t t p s : / / www. s i g ma a l d r i c h . c om/ c a t a l o g / p r o d u c t / s i g ma / b 03 8 3 ? l a n g=e n&r e g i o n =US h t t p s : / / www. s i g ma a l d r i c h . c om/ c a t a l o g / p r o d u c t / a l d r i c h / t 2 5 8 0 1 ? l a n g =e n &r e g i o n =US...

Similar Free PDFs

Lab #8 - Lab 8

- 3 Pages

Post lab 8 - lab 8

- 7 Pages

Docx-8 - lab 8 lab report of 238

- 2 Pages

Lab 8 - lab report

- 6 Pages

Lab 8 - lab assignment

- 4 Pages

Lab 8 - lab report

- 3 Pages

LAB #8 - Lab report

- 4 Pages

Selective Media - Lab 8 - lab 8

- 8 Pages

Magda\'s Lab 8 - Lab 8 write up

- 8 Pages

Math 11 Lab 8 - lab 8

- 7 Pages

ORGO LAB 8 - Weekly lab 8

- 4 Pages

Pre Lab #8 - pre lab 8

- 4 Pages

Lab 8 Section CB - Lab 8

- 4 Pages

Pre lab 8 - Pre lab 8

- 5 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu