Multistep Synthesis of Dulcin from 4-aminophenol PDF

| Title | Multistep Synthesis of Dulcin from 4-aminophenol |

|---|---|

| Author | Alice Nguyen |

| Course | Strategies in Drug Synthesis |

| Institution | University of Technology Sydney |

| Pages | 23 |

| File Size | 1.2 MB |

| File Type | |

| Total Downloads | 68 |

| Total Views | 133 |

Summary

Report of Laboratory Practical ...

Description

MULTISTEP SYNTHESIS OF DULCIN FROM 4-AMINOPHENOL By: Sandy Liu & Alice Nguyen Abstract A multistep synthesis was carried out to produce (4-ethoxyphenyl) urea otherwise known as dulcin. The starting compound, 4-aminophenol underwent nucleophilic acyl substitution with acetic anhydride to form acetaminophen. Following this, through Williamson ether synthesis, acetaminophen reacted with sodium hydroxide and bromoethane to give phenacetin. As a result of insufficient yield of phenacetin, 4-butoxyacetanilide was provided to carry out the subsequent steps. Hydrolysis of 4-butoxyacetanilide and nucleophilic addition with urea consequently gave (4-butoxyphenyl) urea instead of dulcin ((4-ethoxyphenyl) urea) with a yield of 4.77% (0.138g).

1. INTRODUCTION Discovered in 1883 by Joseph Berlinerblau, dulcin is an artificial sweetener 250 times sweeter than sucrose. Although it was preferred over its competitor saccharin for not containing a bitter aftertaste, scientists later on questioned its safety for consumption. Found to be carcinogenic it is prohibited from usage in the food industry in most countries (Goldsmith 1986). Despite this, studies have suggested that dulcin can be useful in the medical field as an analgesic and diuretic (Rosenbaum 2011; Wilcox, Beyer & Carl 1957).

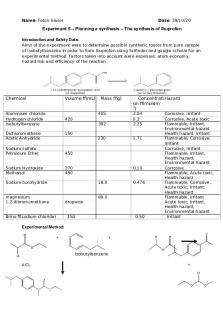

Figure 1 Scheme 1 For this experiment, dulcin was synthesised following scheme 1 which included four main reactions; nucleophilic acyl substitution, Williamson ether synthesis, hydrolysis and nucleophilic addition. This method was adapted from Williams, Williams & Rodino 2000. The starting compound 4-aminophenol acted as a nucleophile to attack the electrophile, in this case the acetic anhydride. With triethylamine providing a basic environment, the amine group attached to the phenol proceeded to attack the anhydride carbonyl group to form a tetrahedral intermediate. Due to its instability, the very electronegative oxygen donated its lone pair to

reform the double bond, thereby expelling the leaving group in the form of acetoxy. The hydrogen on the positively charged amine is then attacked by the acetoxy group to form acetaminophen and methanoic acid (refer to scheme 1 reaction A).

Figure 2. Scheme 1 reaction A Acetaminophen subsequently underwent Williamson ether synthesis to produce phenacetin. In the presence of sodium hydroxide, the alcohol group on acetaminophen deprotonates to produce an alkoxide which is then prone to an SN2 reaction with alkyl halides. Using bromoethane, the slightly more positive ethyl group is attacked by the negatively charged alkoxide to provide phenacetin and sodium bromide (refer to scheme 1 reaction B).

Figure 3. Scheme 1 reaction B Previously produced phenacetin was subjected to hydrolysis in excess hydrochloric acid to give the p-phenetidine hydrochloride salt (refer to scheme 1 reaction C). TLC was utilised to monitor the disappearance of starting material and hence production of the salt (refer to scheme 1 reaction C). This intermediate is then immediately treated with sodium carbonate to basify the solution (pH of 6.0-6.5) and convert the salt back to its amine group. Once sufficiently basified, the phenolic amine then attacks the urea carbonyl group to form the intermediate D1. Instability of the electronegative oxygen was the driving force for the lone pair to reform the double bond and consequently expelled amine as the leaving group. This leaving group’s lone pair proceeds to attack the extra positive charge on the phenolic amine to yield dulcin.

Figure 4. Scheme 1 reaction C

D1

Figure 5. Scheme 1 reaction D

2. METHOD Part A – Synthesis of Acetaminophen In a fume hood, place triethylamine (25 mL) and acetic anhydride (15 mL) in a 150mL silicon stopper fitted conical flask. Then cool this flask in an ice bath and add 4-aminophenol (1.50 g). Remove the flask from the ice bath and allow the reaction to continue for 15 minutes whilst occasionally stirring with a spatula, a precipitate will gradually form. Dissolve this residue in ethyl acetate (60 mL) to form a solution. With the resulting solution in a separating funnel use water (40 mL) & brine (40 mL) to wash the organic layer. Proceed to dry over magnesium sulfate, filter and remove the solvent via rotary evaporation. Then recrystallise using a minimum amount of water and carry out analysis of the compound via proton NMR, IR &

melting point. Part B – Synthesis of Phenacetin To a round-bottom flask with acetaminophen (0.2 g; 0.0013 moles) add 0.5M ethanolic NaOH (0.8 equivalent of acetaminophen; 2 mL). Then heat the reaction at reflux for 30 minutes. Remove and to the hot solution add iodoethane (5 equivalent of acetaminophen; 0.4 mL) then return to reflux until completion. Meanwhile prepare a flask with a mixture of ice water (20 mL). Once the reflux is done, remove the round-bottom flask, allow to cool to room temperature and vacuum filtrate into this ice water flask. Phenacetin will precipitate from the filtrate upon contact with the cold water. Vacuum filtrate again to obtain crude phenacetin. Obtain the yield, melting point, NMR & IR before proceeding to part C. Part C & D – Synthesis of Dulcin From part B, add 7 mL of 6M hydrochloric acid; 7.5 mole equivalents to phenacetin. Reflux the solution for 30 minutes then TLC, if reaction incomplete, reflux further 30 mins or until reaction has gone to completion, the solution should become clear. Very slowly, add sodium carbonate while stirring the solution (until basified enough); will produce CO2 vigorously. The pH of the solution should become pH 6-6.5 (acidic). Add 1.2 g of urea; 3.6 mole equivalent to phenacetin and 6 drops of 1M acetic acid solution. Reflux for one hour or until reaction has gone to completion. Cool solution in ice bath to precipitate dulcin and recrystallise with water. Collect dulcin via vacuum filtration. Wash crystal with minimum ice water to remove traces of acid. Obtain M.P, IR and NMR of dulcin.

3. RESULTS 3.1 Part A 3.11 Physical Constants Table 1. Physical characteristics of reactants and products Compound

Mol. Wt (g/mol)

B.P (oC)

M.P ( C)

4-aminophenol

109.128

284

187

1.20

Acetic Anhydride

102.09

139

-73

1.08

Trimethylamine

101.19

89

-114

0.726

Ethyl Acetate

88.11

77.10

-83.60

0.902

Acetaminophen

151.16

>500

169 (Literature) 155-156 (Exp.)

1.30

3.12

o

Density (g/ml)

Quantities and physical description of reactants and products

Table 2. Quantities and description of reactants and products Quantities

Physical description

4-aminophenol

1.50 g

White or reddish-yellow crystals

Acetic anhydride

15 mL

Colourless liquid

Triethylamine

25 mL

Colourless liquid

Ethyl acetate

60 mL

Colourless liquid

Acetaminophen

0.8568g

White crystalline solid

Reactants

Products

3.13

IR Spectra

Figure 6. IR spectrum of Acetaminophen Table 3. Frequency Assignment of Acetaminophen Spectrum Frequency (cm-1)

Assignment

3367

N-H stretch (2° amide)

1736

C=O Stretch

1688

C=C (Aromatic) Stretch

1228

C-O Stretch

859

Sp2 C-H bend

3.14

Proton NMR spectra

Figure 7. H-NMR Spectrum of Acetaminophen

Table 4. PPM assignment of acetaminophen spectrum PPM

Assignment

H’s

Type

2.288

E

3

s

7.048

B

2

d

7.262

D

1

s

7.507

C

3.15

2

d

Theoretical Yield

mass used molar mass 1.50 109.128

Moles of 4-aminophenol = =

= 0.01374532659 mol Moles of acetic anhydride = =

Volume × density molar mass 15 ×1.08 102.089

= 0.1586850689 mol Therefore, the limiting reagent is 4-aminophenol. Hence moles of 4-aminophenol = moles of acetaminophen Theoretical yield = 4-aminophenol moles x acetaminophen molar mass = 0.00137453265 x 151.165 = 0.2077812294 g 3.16 Percentage of actual yield % yield = =

actual yield x 100% theoretical yield 0.8568 x 100% 0.2077812294

= 44.8548% 3.2 Part B 3.21

Physical Constants

Table 5. Physical characteristics of reactants and products Compound

Mol. Wt (g/mol)

B.P ( C)

M.P ( C)

Bromobutane

137.02

100-104

-112.5

1.276

Sodium Hydroxide

39.997

1388

323

2.13

Ethanol

46.069

79

-114.1

0.789

o

o

Density (g/ml)

Phenacetin

179.219

242-245

137.5

N/A

4-butoxyacetanilide

207.273

377

100-114 (Literature) 116 (Exp.)

1.057

3.22 Quantities and physical description of reactants and products Table 6. Quantities and description of reactants and products

Reactants

Products

3.23

Quantities

Physical description

Acetaminophen

3.75 g

White crystalline solid

Bromobutane

2.85 mL

Colourless liquid

Ethanol

5 mL

Colourless liquid

Sodium hydroxide

15 mL

Colourless liquid

Phenacetin 4-butoxyacetanilide

0.05g 4g

White crystalline solid White crystalline solid

IR Spectra

Figure 8. IR spectrum of Phenacetin Table 7. IR assignment of Phenacetin Frequency

Assignment

3274

N-H stretch (2° amide)

2927 & 2991

Sp² C-H stretch

1656

C=O stretch

1604

C=C stretch (Aromatic)

1550

N-H bend

1243

C-O stretch

739

Sp² C-H bend

Figure 9. IR spectrum of 4-butoxyacetanilide Table 8. IR assignment of 4-butoxyacetanilide Frequency

Assignment

3305

N-H stretch (2° amide)

2936-2966

Sp2 C-H Stretch

1663

C=O Stretch

1607

C=C (Aromatic) Stretch

1242

C-O Stretch

736-810

Sp2 C-H Bend

3.24

Proton NMR spectra

Figure 10. H-NMR Spectrum of Phenacetin

Table 9. PPM assignment of Phenacetin PPM

Assignment

H’s

Type

1.411

A

3

t

2.179

F

3

s

4.017

B

2

q

7.2 (Estimate)

E

1

s

6.839-6.856

C

2

d

7.268-7.386

D

2

d

Figure 11. H-NMR Spectrum of 4-butoxyacetanilide

Table 10. PPM assignment of 4butoxyacetanilide PPM

Assignment

H’s

Type

0.952-0.981

A

3

t

1.472-1.486

B

2

sextet

1.731-1.761

C

2

p

2.138-2.145

H

3

s

3.917-3.943

D

2

t

6.828-6.845

E

2

s

7.262-7.373

F

2

s

3.25 Theoretical yield of Phenacetin

Moles of acetaminophen = =

mass used molar mass 0.2000 151.16

= 0.00132310135 mol Moles of ethanolic sodium hydroxide = concentration x volume = 0.5 x 0.002 = 0.001 Therefore, the limiting reagent is acetaminophen. Hence moles of acetaminophen = moles of phenacetin Theoretical yield = acetaminophen moles x phenacetin molar mass = 0.00132310135 x 179.219 = 0.2371249008 g 3.26 Percentage of actual yield % yield = =

actual yield x 100% theoretical yield 0.05 x 100% 0.2371249008

= 21.08593397% 3.25

Theoretical yield of 4-butoxyacetanilide

Moles of acetaminophen = =

mass used molar mass 3.75 151.16

= 0.0248081503 mol Moles of sodium hydroxide = concentration x volume = 3 x 0.015 = 0.045 Therefore, the limiting reagent is acetaminophen. Hence moles of acetaminophen = moles of 4-butoxyacetanilide Theoretical yield = acetaminophen moles x 4-butoxyacetanilide molar mass = 0.0248081503 x 207.273 = 5.142059737 g 3.26 Percentage of actual yield

% yield = =

actual yield x 100% theoretical yield 4.0 g x 100% 5.142059737

= 77.78983917 %

3.3 Part C & D 3.31 Physical Constants Table 11. Physical characteristics of reactants and products Compound

Mol. Wt (g/mol)

B.P (oC)

M.P (oC)

Density (g/mL)

Hydrochloric acid

36.46

-85

-114.2

1.2

4-butoxyacetanilide

207.273

377

100-114

1.057

Sodium carbonate

105.988

Decomposes

851

2.5

Urea

60.055

196

132-135

1.335

Acetic acid

60.052

117.9

16.6

1.05

Dulcin

180.207

Decomposes

173

N/A

(4-butoxyphenyl)urea

208.261

N/A

N/A

N/A

3.32 Quantities and physical description of reactants and products Table 12. Quantities and description of reactants and products

Reactants

Product

Quantities

Physical Description

4-butoxyacetanilide

1.004g

Light Brown Crystalline Solid

Hydrochloric Acid

7mL

Colourless liquid

Urea

1.2g

White Crystalline Solid

(4-butoxyphenyl)urea

0.138g

Brown Crystalline Solid

3.33

IR Spectra

Figure 12. IR spectrum of 4-butoxyphenylurea Table 13. IR assignment of 4-butoxyohenylurea Frequency

Assignment

3412

N-H Stretch (2 ∘ amidee)

2871-2957

Sp2 C-H Stretch

1675

C=O Stretch

1612

C=C stretch (Aromatic)

1248

C-O Stretch

821

Sp2 C-H bend

3.34

Proton NMR spectra

Figure 12. H-NMR Spectrum of 4-butoxyphenylurea

Table 14. PPM assignment of 4-butoxyohenylurea PPM

Assignment

H’s

Type

0.949-0.990

A

3

t

1.435-1.495

B

2

sextet

1.704-1.807

C

2

p

3.882-3.945

D

2

t

6.777-6.795

E

2

s

6.842-6.973

G-H

3

s

7.156-7.173

F

2

s

3.35

TLC

Figure 13. TLC plate of 4-butoxyphenylurea

Distance spotting moved Retention Factor of Starting material = Distance solvent moved ¿ baseline ¿ baseline¿ ¿ 3 = 5 = 0.6

Distance spotting moved Distance solvent moved Retention Factor of Reaction Mixture Spot near baseline = ¿ baseline ¿ baseline¿ ¿ 1 = 5 = 0.2 Retention Factor of Reaction Mixture Top of Streak =

=

Distance spotting moved Distance solvent moved ¿ baseline ¿ baseline ¿ ¿ 3 5

= 0.6 3.36

Theoretical yield (4-butoxyphenyl)urea

mass used molar mass 1.004 = 207.273

Moles of 4-butoxyacetanilide =

= 0.004843853276 mol Moles of Hydrochloric acid = concentration x volume = 6 x 0.007 = 0.042 Moles of Urea = =

mass used molar mass 1.20 60.055

= 0.01998168346 mol Therefore, the limiting reagent is 4-butoxyacetanilide . Hence moles of (4-butoxyphenyl)urea = moles of 4-butoxyacetanilide Theoretical yield = 4-butoxyacetanilide moles x (4-butoxyphenyl)urea molar mass = 0.004843853276 x 208.261 = 1.008785727 g 3.26 Percentage of actual yield % yield = =

actual yield x 100% theoretical yield 0.138 g x 100% 1.008785727

= 13.6798129 %

DISCUSSION The synthesis of dulcin required four main reactions; nucleophilic acyl substitution, Williamson ether synthesis, hydrolysis and nucleophilic addition.For the first reaction, where 4-aminophenol underwent nucleophilic acyl substitution with acetic anhydride, phenacetin was produced with a yield of 44.85% which is satisfactory when compared to the yield range of 35% to 70% (Royal Society of Chemistry 2016). In order to determine if the targeted intermediate was synthesised IR and proton NMR was conducted. IR spectrum for reaction A indicated that the product was indeed acetaminophen as indicated in the characteristic peaks at 3367 and 859 cm-1, corresponding to a secondary amine stretch and sp2 C-H bend for a para-substituted aromatic. However the characteristic O-H broad peak was not present when compared to literature (refer to appendix A). It is speculated that this may be due to insufficient removal of water in the sample, which may have interacted with the acetaminophen hydroxy group and hence dampened the phenolic absorption in IR. Upon further inspection of NMR, again impurities were suspected by the chemical shifts at 1.583 and 2.170 ppm which indicated residual water and acetone respectively. Moving further downfield, the singlet at 2.288, doublet of doublet at 7.507 and 7.048 and small broad singlet at 7.262 respectively indicate the presence of a shielded methyl group, a para-substituted aromatic along with an amide. The experimental melting point of 155-156oC was quite low compared to the literature value of 169 oC, again this can be contributed to insufficient removal of water and solvent. Overall, these results collectively indicate that acetaminophen was successfully synthesised. The subsequent reaction required acetaminophen to undergo the Williamson ether synthesis with sodium hydroxide and ethyl iodide. This reaction was successful with the targeted intermediate of phenacetin produced, but resulted in quite a low yield of only 21.09%. It was hypothesised that the volatile nature of ethyl iodide (vapourised thus unable to react with the starting material, acetaminophen) could have contributed to this. The key new bond being formed from this reaction was the addition of an ethyl group to the phenolic oxygen. Hence IR analysis of this product would be quite similar to the previously formed acetaminophen...

Similar Free PDFs

SYNTHESIS OF DIMETHYL ETHER

- 54 Pages

Synthesis of Isopentyl Acetate

- 4 Pages

Synthesis of Sudan-1

- 4 Pages

The synthesis of Ibuprofen

- 4 Pages

Synthesis of methyl orange

- 9 Pages

Synthesis of Aspirin

- 10 Pages

Synthesis of Acetanilide

- 5 Pages

Synthesis of p-nitroacetanilide

- 6 Pages

Synthesis of Flavonol 2

- 13 Pages

Synthesis of Cyclohexene

- 8 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu