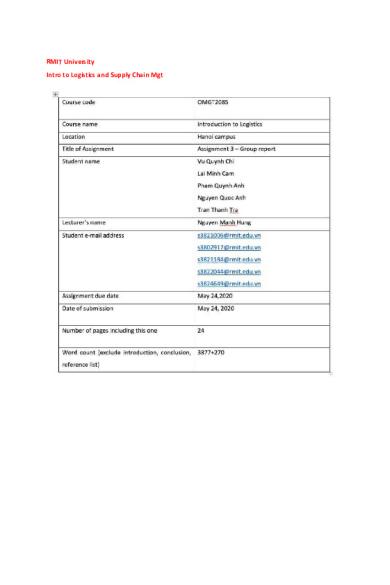

Sample Final Decathlon Hanoi G1 OMGT 2085 Group 4 Group Work Week 11 PDF

| Title | Sample Final Decathlon Hanoi G1 OMGT 2085 Group 4 Group Work Week 11 |

|---|---|

| Author | Minh Hoang |

| Course | Introduction to logistic & supply chain management |

| Institution | Royal Melbourne Institute of Technology University Vietnam |

| Pages | 24 |

| File Size | 952.7 KB |

| File Type | |

| Total Downloads | 91 |

| Total Views | 134 |

Summary

HD assignment, no other fucking details needed for stupid studocu requirement...

Description

RMIT University Intro to Logistics and Supply Chain Mgt

Table of content I.

Executive summary

II.

Introduction

III.

Identify a, Demand forecasting b, Inventory management c, Transportation d, Production planning e, Customer service

IV.

Discussion a, Discussion A a.1, Supply Chain‘s core competencies a.2, Lean production - Pull-based systems - ATO for Footwear – Strengths and Disadvantages a,3, B2C and B2B relationships a,4, Technological changes affect the supply chain b, Discussion B b.1, Transportation management b.2, Customer service b.3, Product planning b.4, Inventory management b.5, Demand forecasting

V.

Conclusion

VI.

Summary of Teamwork

I.

Executive summary

This report analyses Decathlon's sporting goods retailer’s supply chain management, intending to understand the production target of the company and their main objective, which is to satisfy their customer with the company’s product and service. This assignment is broken down into 2 sections, one of them being and identification of Decathlon’s footwear supply and logistic chain, further divided into different aspects: demand forecasting, inventory management, transportation, production planning, and customer service. Several graphs with analysis will be provided for a deeper understanding of this topic. The other part of this report is split into 2 discussions A and B. Discussion A will focus on the core competence of the Decathlon supple chain, their strategy, and how it may be affected by recent newer technologies. Discussion B will list out possible difficulties Decathlon may encounter from their current supply chain strategy, those issues will also be divided into 5 different sections similar to that of the identification. Several solutions will be listed out along with explanations for those at the end, serving as mater to evaluate Decathlon’s overall supply chain to their target and how well they can perform as well as manage risk and errors. The final result indicates that Decathlon fulfilled its objective and manage its supply, inventory, and transportation rather smoothly. However, there still exist several threats to their system and the corporation needs to improve more in their customer service and manufacturing discreetly. Data used in the assignment are taken from multiple sources and also the course’s guest lecture. Materials quoted and included are both academic and non-academic. Information may be displayed incorrectly due to a lack of certain resources and uncertainty of authenticity.

II.

Introduction Decathlon is a French sporting goods retailer, founded in 1976 in France, founded by Michel Leclercq.

To make sports accessible to as many people, the company always thrives to grow and is now known for being the largest sporting retailer in the world with over 1500 stores in 49 countries. They began their business from producing bike frames in 1986, in the present their product ranged from sports and camping equipment, to sports clothing. In the report we will only focus on their footwear products. Their motto is always to make sports available to everyone in all shapes and sizes, they greatly emphasize their customer finding their fitting size with ease thanks to their effective supply chain and warehouse placement. Having a long experience and broad knowledge of logistics and supply chain proves to be advantageous for this sporting titan to understand the flow of things and the challenges they will encounter in this field. Apart from comparing the concept of Modern Logistic to what Decathlon

applied, this assignment will also identify and discuss the core competence of their supply chain network, how the corporation copes with changes in recent technologies. Issues and a couple of resolves will be discussed by the end of the assignments.

III.

Identify – Supply chain processes

As can be seen from the Logistics and supply chain of Decathlon in Vietnam, the process can be separated into various actors with labels. First of all, Decathlon chooses to place its components factories in other countries such as China, India, Bangladesh, etc, Then, these footwear components will be transported by ships or containers to assemble plants in Vietnam (Saigon Garmex, Thai Binh shoes, Dong Tien company). After these factories have completed manufacturing the goods based on the design from France, the finished products are delivered by the airway to CAC Logistics or the main warehouses. There, the products will be evaluated for quality and classified to distribute to smaller warehouses in Hanoi and Ho Chi Minh in suitable quantities. Later on, these products are loaded on trucks to come to Decathlon stores or local retailers (Push Climbing, Bike Café, Saigon Climbing Center, etc). These items are also available on Decathlon’s retail channel. According to Gefco (2019), upstream logistics consists of any activities that provide the company with goods (raw material, work-in-process products, replacement tools, etc) in obedience to agreed mass and time requirement, while downstream logistics involves logistics activities referring to accommodate consumers with finished products. In this case of Decathlon, the upstream section contains component factories, assembly plants, and Decathlon warehouses. In the downstream, transportation, delivery method, and Decathlon stores, retailers, retail channels are the regions where most downstream logistics processes take place. This logistics and supply chain activities are designed to best suit Decathlon in the Vietnam market.

Channel map of Decathlon

a. Demand forecasting The major activity of demand forecasting is calculating based on a predictive evaluation to determine the customer demand for different products in the future. The information gets influenced by both internal and external factors, such as trends, historical sales data, seasonality, etc. This concept contributes to business activities like financial planning, sales and marketing plans, raw material planning, production planning, risk assessment, and so on. Demand forecasting plays an essential role in supply chains. An accurate demand forecasting can determine the amount of desired raw material, work-in-progress cost, and finished goods inventory levels. It helps the company to decrease the Bullwhip effect in the supply chain, which will optimize the inventory levels, lower the stockouts, and avoid over-stocking situations. Moreover, a proper demand forecasting will improve the distribution in planning and logistics, which leads to an increase in customer satisfaction, assist the launch of new products and decline the risk of obsolescence products

For example, Decathlon uses historical data and considers all the internal and external factors that might affect the customer demand to forecast the needs of consumers in the future. This information has helped the company to minimize inventories, reduce stockouts and determine the quantity order to fulfill its customer needs as well as support the company decision on the number of products that will be generated in the next period.

Demand forecasting process b. Inventory management Inventory management supervises the flow of products from ordering, storing to the hand of customers. In the supply chain, inventory management involves particular tasks, such as managing raw materials, components, and finished goods, also warehousing and processing such items. There are three main activities in inventory management: find suppliers, purchase new inventory, and track inventory. The responsibility of evaluating suppliers is to make connections with suppliers that can provide the company with the products or materials needed to conduct and be beneficial. Purchasing new inventory requires managing the amount of inventory that is left or is running low to replenish the materials on time. The last one is tracking inventory. Tracking inventory is ensuring that the company has enough stock to fulfill the customer needs as well as avoid the overstocking situation, differentiate products based on their status, and decline the inventory cost. In the case of Decathlon, the company collaborates with the best suppliers in Vietnam such as Saigon Garmex, TBS shoes, etc to manufacture the best quality product, along with excellent customer service: always on time with the right products.

` Inventory management process c, Transportation Transportation management is a process of moving materials, components, pieces and products from one place to another, from where they are manufactured to where they are needed (Haniefuddin, Shamshuddin & Baba 2013).

Transportation activities include preparing, orchestration, operation and tracking of the product flow (Castell 2013). In other words, in the transportation process, a detailed plan needs to be prepared and show where each vehicle was assigned with an exact route and exact quantity of products. After that, the plan needs to be executed, every vehicle in the plan needs to be tracked while following the plan so that the manager can be informed immediately if some unexpected events take place. This process helps transportation managers assure effective information/ product flows and provide a better customer service. A good transportation system can provide links between organizations, fulfil demand and promote competitiveness in the supply chain.

Transportation process d, Production planning Production planning is a method of planning production and manufacturing merchandises in an organization. It utilizes the resources distribution of staffs’ activities, supplies and manufacturing capacity to satisfy various customers (Fargher, Hugh & Richard ).

Production planners have four key tasks. Firstly, they have to plan and prioritize operation to maximize performance and minimize delays. Secondly, they need to coordinate production workflow for the product line. Also, production planning managers are required to monitor employees jobs to deliver the product on time and within budgets. Finally, the manager’s most important task is to determine manpower, equipment, component material needed for the production process.

A good production planning system can give its organization a better customers service, better inventory control, fewer rush orders, less idle time.

Production planning process (UNARS Technologies n.d)

e, Customer service Customer service is a process of communicating with customers in relation to a product or service to maximize customers satisfaction.

The customer service manager is required to address any issues or complains from their products or services to build a sustainable relationship with their clients.

Customer service factor can create communication value. Customer service represents the face of a company. It is responsible for receiving customer feedback and connecting the company with the mass. Therefore, good customer service can give the company a better brand image. Also, customer service factor can create time value. Good customer service can help cut down time on detecting problem within a company by managing customers feedbacks and timely respond to customers. By lower detecting problems time, the company can higher clients satisfaction.

Customer Service Standards (Mike 2018)

IV. Discussion a, Discussion A a.1, Supply Chain‘s core competencies In general, core competencies are the distinguishing strengths or advantages that a company could have, and that separate it from competitors. Core competence is the basis for improving the competitive edge of a company and it drives brand recognition, sales development and marketing strategies. Decathlon’s purpose is to sustainably make the pleasure and benefits of sports accessible to the many. This is how Decathlon differentiates ourselves from other plays in the marketplace, namely Nike, Adidas and Under Armour. Decathlon focus on the demand of the mass customer with the belief that playing sports is not a privilege but a benefit for all. That is why Decathlon chose to offer a wide choice of 70 sports with affordable equipment and great quality. No matter for customers who are beginners, intermediates or professional players in the sport field, customers can easily choose products with specific functions, reasonable prices which are suitable for their needs. Decathlon honours Vitality and Responsibility. Vitality means Life since Decathlon employees are full of vitality as they are enthusiastic, have a positive mindset and love creating and innovating and always try

to improve and make things around them change for the better. Responsibility means that Decathlon employees are empowered to take action, make decisions and take responsibility of their own. This is also the orientating actions toward sustainable development. Decathlon’s goal is to make products profitable to the company and accessible to users and preserve the environment at the same time. Thanks to the sport or physical activity, Decathlon aims to allow people in fragile situations to have a better quality of life.

a.2, Pull-based systems - Lean production - ATO for Footwear – Strengths and Disadvantages Decathlon applies Pull systems to the Footwear section. Pull-based system brings Decathlon advantages and drawbacks. Strengths: 1.

Improved Quality

Pull-based system attaches special importance to details, aiming to minimization of defects and reworks in production. This means that because products are made in small quantities, quality problems can be detected more easily than with a push program and less error products will be required disposal, which saves time and money for employees to rework goods.

2.

Improved Customer Relationship

Pull system started with the customer’s standpoint. Customers need to be provided with what they want, when they want and where they need it. A company who applies a pull system achieves greater customer satisfaction since products are directly made to meet their expectations. A company is successful as long as the customers are satisfied. If a company always supplies top quality products and services on time, at the right place, those satisfied customers are going to keep on returning, allowing the business to thrive.

3.

Improved workflows efficiency

Pull-based system will raise productivity and prevent team overburden. Workers know when their daily routine is bloated or packed with unnecessary work that has an adverse effect on morale. Reducing workplace uncertainty, as a result of the pull system, will reduce stress and result in increased employee morale.

4.

Waste Minimization

Pull system will remove outdated or aged inventories and decrease production waste as there is no room for seven deadly wastes (Overproduction, Delays, Transporting, Over processing, Inventory, Motion, Making defective parts). After eliminating non-value-adding tasks from systems, the emphasis is on ensuring the necessary value-adding actions operate effectively without disruptions, delays or bottlenecks.

5.

Maximizing Profits

Pull-based system will bring numerous financial benefits to the company. -

A company will operate smoothly as long as there are satisfied customers.

-

Reducing waste, defects, labor, product storage and inventory management contributes extra

money for improving product quality and better products guarantees higher revenue.

Disadvantages: 1.

More sensitive to disturbances

Since pull system practices are related to manufacturer performance, any supply chain and production disruption will raise concerns which affects consumers. Shipping interruptions can cause difficulties to overcome business challenges.

2.

Flexibility Level

Pull systems do not maintain the same level of flexibility as push systems. They are most successful with repetitive manufacturing systems. Thus, the production of a wide range of products would not be facilitated.

3.

Inventory Problem

Usually, in a pull-based system, small amounts of suppliers are stored to reduce inventory costs leading to company dependence on suppliers and hoping they can make adaptations to deliver products fast and effectively. If any disruption of carrying processes occurs, the company will be derailed. Also, Cycle time have great impact on the product

4.

Rushes order may cause stress

The benefits which a Pull-based system brings definitely outweigh its demerits. And this is why Decathlon decides to use the Pull system in the first place.

a.3, B2C and B2B relationships

Relation levels in supply chain There are three major stages: from distribution relationships to collaborations (cooperation and ability to change targets to produce long-term results) and ultimately, strategic partnerships (total integration) seeing greater collaboration.

Forming Relationships Process Model

Logistics relation has 6 periods so the b2c relation will occur after such procedures have been considered. First, tactical evaluation requires understanding of requirements, as well as general approach guidance, good-managed preparation and collecting data analysis. Next, to determine how the partnership is established based on core competency, operators and coordinators. Operators are a crucial partnership factor since the benefits that they offer only happen with collaboration. Coordinators clearly mean factors that ensure drivers establish more positive partnerships. The third step is the assessment of solutions, planning the correct capacity and function for the future plan. The fourth procedure is to grow partner recognition and operate a business model. Business then applies policy and performance development.

Supply chain management process

In the sourcing and integration process, relative to the seller (manufacturer), the buyer (merchandising companies) primarily focuses on the product kit over pertinent information. Buyer provides suggestions on the supplies and the details of different items to add quality to the vendor. Both parties are interested in the design of packaging which is suitable not only for the distribution but also for desirable consumers. They also discuss the productivity associated with environmental issues affecting their companies. For example, Decathlon extends partnerships with DHL Global Forwarding, the world's leading provider of air, sea and road services has announced the cooperation to provide a comprehensive international supply chain which are implemented as part of contract conclusion.

Buyer-supplier distribution and relationship

The prime tactical option during shipment is to collaborate with consumers. Suppliers (producing companies or 3PLs) communicate with consumers because they need to ensure that the right products with the right quantity delivered at the right price are in the right condition and delivered to the right customers at the right time, in the right place. The previous tactical option during delivery is to collaborate with consumers. Suppliers (merchandising companies or 3PLs) communicate with consumers because they need to ensure that the goods delivered are in the right place, the right time and the same price. The relationship relies on drivers (better cost-effectiveness growth, customer service, and profit-making) along with coordinators (similarity to decrease mistakes, shared dedication to integrate laws, and proportional determinants), so all organizations achieve revealed objectives. Business also uses the link to classify customers for strategic collection accordingly.

Supply chain value proposition wit...

Similar Free PDFs

Group 4 Final Project

- 70 Pages

Group 11 Econometrics Final report

- 35 Pages

Group Work 10 - nutrition work

- 1 Pages

Group Assignment STA404 Group 4

- 24 Pages

Courtroom Work group paper

- 4 Pages

Project management group work

- 14 Pages

Econometrics-Midterm group work

- 21 Pages

Group Clinical Work

- 2 Pages

Group 4-Case-Study Final

- 19 Pages

Case study group work

- 3 Pages

CRIThandout - Group work

- 2 Pages

SOCIAL GROUP WORK

- 5 Pages

Human Resource group work

- 1 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu