The Synthesis of Benzocaine, a Common Anesthetic PDF

| Title | The Synthesis of Benzocaine, a Common Anesthetic |

|---|---|

| Course | AP Chemistry |

| Institution | High School - USA |

| Pages | 5 |

| File Size | 201 KB |

| File Type | |

| Total Downloads | 37 |

| Total Views | 151 |

Summary

The purpose of this experiment is to synthesize benzocaine from p‐aminobenzoic acid using an esterification reaction.

...

Description

The Synthesis of Benzocaine, a Common Anesthetic

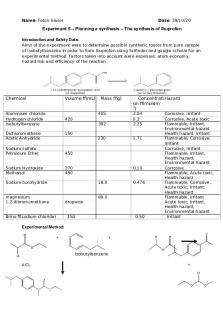

Purpose: The purpose of this experiment is to synthesize benzocaine from p-aminobenzoic acid using an esterification reaction. Chemical Structures/Reactions:

Calculations:

Limiting Reagent: 12g aminobenzoic acid x (1mol/137.14g) x (1mol benzo/1mol amino) x (168.1g/1mol benzo) = 1.45 g Benzocaine 12 ml ethanol x (0.789g/1ml) x (1 mol/46.07g) x (1mol benzo/1mol ethanol) x (165.1g/1mol) = 33.95 g Benzocaine 1.5ml sulfuric acid x (1.84g/1ml) x (1mol/98.08g) x (1mol benzo/1mol sulf) x (165.19g/1mol) = 4.65 g Benzocaine 20ml sodium carbonate x (2.54g/1ml) x (1mol/103.99g) x (2mol benzo/1mol sodium) x (165.19g/1 mol) = 158.35 g Benzocaine - Aminobenzoic Acid is the limiting reagent Theoretical Yield: 12g aminobenzoic acid x (1mol/137.14g) x (1mol benzo/1mol amino) x (168.1g/1mol benzo) = 1.45 g Benzocaine - Theoretical Yield = 1.45 g Benzocaine % Yield: % yield = experimental/actual x 100 = (0.259 / 1.45) x 100 = 17.87% Rf Value: Rf = Distance Spot Traveled / Distance Solvent traveled Results: - Mass of final product = 0.2591 grams - % yield = experimental/actual x 100 = (0.259 / 1.45) x 100 = 17.87% - Melting point of product: 88.8 - 89.6 degrees Celsius - TLC: Spot 1 = Starting Material Spot 2 = Product

-

Distance Spot Traveled (mm)

Distance Solvent Traveled (mm)

Rf Value

Spot #1

2.5

6.7

0.37

Spot #2

5.0

6.7

0.75

IR Interpretation: - 3 amine peaks - 3417.09 - 3225 - Sp3 CH - 2970.71 - Carbonyl - 1676.22

Discussion Questions: 1. The results of our TLC show us that our product is fairly pure. There is enough separation and difference in Rf values of the starting material and product to infer that there is no evidence for the presence of starting material (p-aminobenzoic acid) in our product (benzocaine). 2. Our experimentally determined melting point range of our product is 88.8-89.6 degrees celsius. We did not obtain an exact melting point. However, from this melting point range, we can infer that our product was almost completely pure. The actual melting

point of Benzocaine us 92 degrees celsius and the melting point of p-aminobenzoic acid is 157-189 degrees celsius. Considering our product’s melt temp was very close to 92, we can assume our product is almost completely pure. 3. Our product percent yield for benzocaine is 17.87%. This is a considerably low percent yield. This could have been caused by a number or lurking variables or simply from human error. First, we did not let our final product dry over the vacuum for an extended amount of time, and we could have not retrieved all of the product from the round bottom flask or from the filter paper. Aside from that, we noticed that throughout the entire experiment, our product was a different color than that of the groups around us. We are not completely sure if this had anything to do with the low percent yield, but have a feeling we may have made a small human error in order to cause this color difference. 4. The experimentally found melting point range for benzocaine was found to be 88.8-89.6 degrees celsius. The known melting point for benzocaine is 92 degrees celsius. We consider these to be very similar, however, the small difference could be attributed to our product being slightly impure. 5. When comparing the IR spectrums of both the starting material (p-aminobenzoic acid) and the final product (benzocaine), the spectrums continue to show similar peaks between the two materials with the majority of peaks found at 2000 or less cm-1. Additionally, there are a smaller set of peaks between the 3000-3500 cm-1 range on the IR spectrum analysis of both materials. This tells us that some of the starting material has remained making the product not completely pure.

Conclusion: In conclusion, this experiment was partly successful. The purpose of this experiment was to synthesize benzocaine from p-aminobenzoic acid using an esterification reaction process. We started this by adding 1.218 g of p-aminobenzoic acid and 12 mL of absolute ethanol into a 50 mL round bottom flask and mixed until the p-aminobenzoic acid dissolved. After this we added 1.0 mL of H2SO4. We then heated the mixture for 30 minutes, adding extra sulfuric acid around 20 minutes to help ensure the reaction occurred, this being indicated by the mix becoming clear. After this we added 26 mL of Na2CO3 slowly, one mL at a time dropwise, to get a pH of 9. Once this was done we used gravity filtration and rotary evaporation to collect 0.2591 g of benzocaine, this left us with a 17.87% percent yield which could be due to product being lost due to transferring between containers. Our experimental melting point was very similar to the actual melting point of the product. The IR spectrums of both benzocaine and p-aminobenzoic acid you can see peaks at similar cm^-1 but the peaks in the benzocaine IR are smaller than those of the starting material....

Similar Free PDFs

The synthesis of Ibuprofen

- 4 Pages

Synthesis of a Coumarin

- 5 Pages

Title The Synthesis of Alum

- 2 Pages

Local Anesthetic Agents + MRD

- 7 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu