72720739 Jsa Grinding Welding Gas Cutting PDF

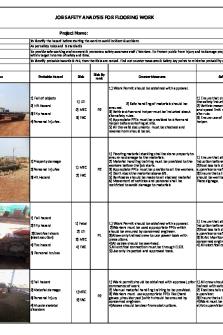

| Title | 72720739 Jsa Grinding Welding Gas Cutting |

|---|---|

| Author | Anonymous User |

| Course | Schrijfvaardigheden Engels |

| Institution | Anton de Kom Universiteit van Suriname |

| Pages | 3 |

| File Size | 107 KB |

| File Type | |

| Total Downloads | 7 |

| Total Views | 140 |

Summary

risico analyse ...

Description

Project:

JOB SAFET ANALYSIS

Company Logo

Ref No.: Rev No.:

Grinding, Welding & Gas cutting

Page:

Prepared by:

Reviewed by:

Approved by:

Date:

Step No. 1

Description of Task Step

Work start-up & obtaining PTW

Supervisor

Make sure guards are fitted to all moving parts Ensure the proper use of guards Inspect the grinding discs prior to starting work (ring test) Make sure that disc is compatible with the grinding machine Check the RPM of disc & machine Proper PPE (Gloves + Mask). Correct installation of Grinder Wheel. Gas monitor correctly sited.

Spark containment to be used.

Invalid permit

Lack of competency

Haste or shortcut

Grinding

PTW applicant Supervisor PTW holder

Unauthorized work

Lack or poor communication

Rotating equipment sparks. Damaged grinding disc

Electrocution.

High Pressure air

Responsible Person

Obtain a hot work permit before starting the job Get the permit validated for the specific day Supervisor must ensure that all work activities are carried out by competent personnel Conduct Toolbox meeting, review the Method statement and Job safety analysis to all craftsmen involved in the work activities. Responsible person will conduct inspection, monitor the work activities and have to ensure safety standards and procedures are strictly adhered to.

2

Control Measures/ Preventive Measures

Hazard

1 of 3

Project:

JOB SAFET ANALYSIS

Company Logo

Ref No.: Rev No.:

Grinding, Welding & Gas cutting

Step No.

Description of Task Step

3

4

Gas Cutting

Welding

Control Measures/ Preventive Measures

Hazard

Flying object/eye injuries

Page:

Only experienced personnel to use the equipment.

Wear a face shield while grinding

Make sure an eye wash station is available nearby

2 of 3

Responsible Person

Burns. Fire Hazard. Explosion. Tripping. Damaged or leaking cylinders or hoses

Proper isolation of system. All cylinders to be secured. Flame arrestor between the cylinder & torch Hoses in good condition. Proper PPE. Trained Fire Watch. Gas Monitor correctly sited. Correct Fire Extinguisher(s). Deployment of Experienced personnel. Cordoning of the area. Fire Blanket. Inspect the cylinders & hoses before starting the job

Supervisor & Workers

Fire Hazard

Supervisor & Workers

Burns.

Electrocution/ Spatter burns

Before starting welding make sure the area is clear of all types of combustible materials Provide a fire blanket on site Make sure fire extinguishers are available on site Wear proper PPE for welding ie., leather jackets, Gloves, welding goggles/welding mask, Trained Fire Watch. Gas Monitor correctly sited. Certified Equipment and to be sited as near as

Damage cable

Project:

JOB SAFET ANALYSIS

Company Logo

Ref No.: Rev No.:

Grinding, Welding & Gas cutting

Step No.

Description of Task Step

Control Measures/ Preventive Measures

Hazard

Hot tabs end pieces of welding rods.

Sparking

Damage cable

Page:

UV rays

possible to work site. Proper earthing of equipment. Certified Welder. Make sure spark containment is used such as a welding hood/fire blanket. Ensure that rod holder is in good condition. Ensure that forward and return cables are in good working condition. Use proper cable connector for extension. If cables are crossing the road then ensure proper protection. The welder & the welder helpers must wear welding goggles

3 of 3

Responsible Person...

Similar Free PDFs

WELDING REPORT GAS WELDING

- 1 Pages

JSA-Pondasi

- 2 Pages

JSA WAREHOUSE

- 1 Pages

CUTTING TOOL DAN CUTTING FLUID

- 45 Pages

CONTOH JSA

- 13 Pages

Contoh JSA

- 5 Pages

Grinding Process

- 5 Pages

welding teknologi

- 425 Pages

ECG - ELECTROCHEMICAL GRINDING

- 4 Pages

PROSES MANUFAKTUR (CUTTING)

- 17 Pages

Cost cutting termination

- 1 Pages

Welding Inspection Handbook

- 29 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu