Jsa 7 XLS

| Title | Jsa 7 |

|---|---|

| Author | kranthi Kumar |

| File Size | 4.2 MB |

| File Type | XLS |

| Total Downloads | 226 |

| Total Views | 269 |

Summary

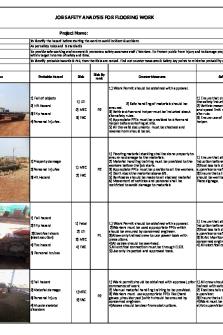

JOB SAFETY ANALYSIS FOR FLOORING WORK Project Name: JSA No. 005/JULY/13 1 Definition To identify the hazard before starting the work to avoid incident & accident. 2 Scope As per safety rules and IS standards To provide safe working environment & promote a safety awarness staff / Workers. To ...

Description

JOB SAFETY ANALYSIS FOR FLOORING WORK Project Name: JSA No. 005/JULY/13 1 Definition To identify the hazard before starting the work to avoid incident & accident. 2 Scope As per safety rules and IS standards 3 Objectives 4 Procedure To identify probable hazards & risk, then the Risks are ranked. Find out counter measures & Safety key points to minimize probability of hazards. 5 MTC-Medical Treatment Cases, FAC-First Aid Cases Sl. No. Activity Working Pics Probable Hazard Risk Counter Measures Safety key Points Revised risk Job Responsibility 1 P2 P4 2 P2 P4 3 P1 P3 4 P2 P4 To provide safe working environment & promote a safety awarness staf Workers. To Protect public from injury and to damage properties . To ensure Safe works without disruption & to complete them within target in terms of safety and time. Risk By rank Transportation of channel and reinforcement and Flooring material to site. 1) Fall of objects 2) Hit Hazard 3)Trip hazard 4)Personal injuries. 1) LTI 2) MTC 3) FAC 1.) Work Permit should be obtained with approval. 2) Safe handling of materials should be ensured. 3) Vehicle driver and helper must be inducted about site safety rules. 4) Appropiate PPEs must be provided to driver and helper before entering at site. 5) All the valid documents must be checked and reverse horn should be ok. 1) Ensure that driver and helper have got the safety induction. 2) Vehicle movements should be controlled and speed limit must be maintaied as per site rule. 3) Ensure use of PPEs by vehicle driver and helper. 1) Site Engineer 2) Site Supervisor 3) Site safety Ofcer Unloading of fooring materials and reinforcement at site 1)Property damage 2)Personal Injuries 3)Hit Hazard 1) MTC 2) FAC 1) Flooring material stacking shall be done properly to ensure no damage to the materials. 2) Material handling training must be provided to the workers before the job starts. 3) Appropiate PPEs must be provide to all the workers. 4) Don't stack the material above 6f . 5) Barricades should be made to all stacked material 6) Movement of vehicles and personal shall be restricted to avoid damage to materials 1) Ensure that all crew got the safety induction before deploying the work. 2)Tool box talk done by concerned supervisor or safety ofcer 3)Ensure that all stacked material should be well barricaded 4) Place signage. 1) Site Engineer 2) Site Supervisor 3) Site safety Ofcer Making of channel in steel yard and cutng of reinforcement as per drawing with the use of portable electrical tools 1) Fall hazard 2)Trip hazard 3)Electrical shock (electrocution) 4)Fire hazard 5) Personal bruises 1) Fatal 2) LTI 3) MTC 4) FAC 1.) Work Permit should be obtained with approval. 2)Workers must be used appropriate PPEs which should be ensured by concerned engineer. 3)Allow only trained crew to use power tools with precautions. 4)All cables should be overhead. 5.All elctrical connection must be through ELCB. 5)Use only Inspected and approved tools. 1) Ensure that all crew got the safety induction before deploying the work. 2)Tool box talk done by concerned supervisor or safety ofcer . 3) Strict Monitoring by supervisor or concerned engineer. 4) All electrical connection through ELCB. 1) Site Engineer 2) Site Supervisor 3) Site safety Ofcer Shifing of reinforcement , channel and Flooring material from yard to work spot (Manually) 1)Fall hazard 2)Material damage 3)Personal injury 4)Muscle skeletal disorders 1)MTC 2)FAC 1) Work permit should be obtained with approval,prior commence of work. 2) Manual material handling training to be provided. 3) Workers must use appropriate PPEs like (hand gloves ,shoulder pad )which should be ensured by concerned engineer. 4)Access should be clear from obstructions. 1) All crew should be experienced & trained with safety induction. 2) Tool box talk done by concerned supervisor. 3)Ensure that all the crew wear the PPE. 4)Work must be carried out under the strict supervision 1) Site Engineer 2) Site Supervisor 3) Site safety Ofcer...

Similar Free PDFs

JSA-Pondasi

- 2 Pages

JSA WAREHOUSE

- 1 Pages

CONTOH JSA

- 13 Pages

Contoh JSA

- 5 Pages

7 Bioenergetica - Apuntes 7

- 23 Pages

7-Platelmintos - Apuntes 7

- 20 Pages

7 Lösung 7

- 10 Pages

Test 7 - test 7

- 6 Pages

7

- 2 Pages

Leccion 7 - Apuntes 7

- 15 Pages

7 - Lecture notes 7

- 1 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu