Continuous cooling diagrams PDF

| Title | Continuous cooling diagrams |

|---|---|

| Author | sophie lord |

| Course | Materials Science I |

| Institution | Newcastle University |

| Pages | 2 |

| File Size | 81.9 KB |

| File Type | |

| Total Downloads | 34 |

| Total Views | 156 |

Summary

Continuous cooling diagrams...

Description

Continuous Cooling Diagram: Continuous cooling transformation curves stop halfway down, as all phases cannot be obtained. Different cooling rates lead to different compositions and cooling faster than the critical cooling rate can lead to the formation of 100% martensite. The critical cooling rate is the minimum rate at which 100% martensite can be formed. The martensite is hard and very brittle, so will need to be tempered before use. The slowest cooling rate at which fully martensitic structure is formed is the critical cooling rate. It is the minimum rate of quenching that will produce a totally martensitic structure. The difference between CCT curves and ITT curves is the method of cooling. In ITT diagrams, you cool down to a transformation temperature and then keep the temperature constant until the transformation of austenite to the product is complete, before cooling to room temperature. In CCT diagrams, there is a continuous cooling (i.e. no holding of temperature) and the components are cooled at varying rates. Quenching in oil as oppose to water will result in a slower rate of cooling.

For example, using the eutectoid 0.8% C continuous cooling diagram above, cooling to 150ºC at a rate of less than 35ºC/s will result in 100% pearlite.

Two common heat treatments are annealing and normalising, but the main difference between the two is the rate of cooling of the sample. In the annealing process, a sample is put into a furnace and the temperature is increased until the sample is homogeneous in the austenite region . It is then left inside the ‘off’ furnace to allow it to cool very slowly in order to form coarse pearlite. This helps to reduce the hardness, increase ductility and help eliminate internal stresses. In the normalising process, a furnace is used to raise the temperature of the steel and then allowing it to cool by exposing it to room temperature air directly after it has been heated. This heating and cooling alter the microstructure of the metal, reducing the hardness and increasing ductility. An alloy steel is a type of steel that is alloyed with a variety of elements in total amounts between 1-50% by weight, to improve its mechanical properties. Stainless steel is an alloy of iron with a minimum of 10.5% chromium, which produces a thin layer of oxide on the surface of the steel that prevents corrosion to the surface....

Similar Free PDFs

Continuous cooling diagrams

- 2 Pages

COOLING TOWERS 1

- 6 Pages

Pre-Cooling

- 13 Pages

BAHAN COOLING TOWER

- 12 Pages

Prinsip Kerja Cooling Tower

- 5 Pages

ppt cooling tower.ppt

- 39 Pages

Muscle diagrams

- 4 Pages

CHE504 Lab 2 Cooling Tower

- 10 Pages

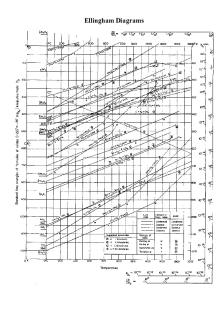

Ellingham diagrams

- 4 Pages

Ellingham diagrams

- 4 Pages

Algebra of Continuous Functions

- 40 Pages

Present Continuous ejercicios

- 3 Pages

Cooling Water System

- 2 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu