Synthesis of Isopentyl Acetate PDF

| Title | Synthesis of Isopentyl Acetate |

|---|---|

| Author | Mercedes Erpelding |

| Course | Organic Lab |

| Institution | University of Minnesota, Twin Cities |

| Pages | 7 |

| File Size | 239.6 KB |

| File Type | |

| Total Downloads | 9 |

| Total Views | 192 |

Summary

Lab Report ...

Description

Synthesis of Isopentyl Acetate Mercedes Erpelding Chemistry 2311 TA: Martezin October 4th 2017

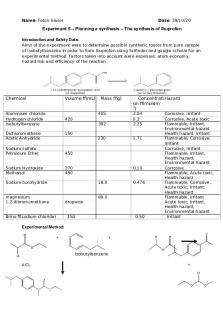

Purpose: The type of reaction performed was a acid-catalyzed Fischer Esterification of Isopentyl alcohol with Glacial Acetic Acid to form Isopentyl Acetate. First, the reaction required refluxing to heat the mixture to the required boiling point and allow the solvent to recondense back into the reaction flask. Using Le Chatelier’s Principle, the position of the equilibrium was moved towards the products by removing product from the reaction due to distillation. After distillation, boiling point, H NMR spectroscopy and IR was used to analyze the product. Reaction Scheme: The esterification of isopentyl acetate from isopentyl alcohol and acetic acid produces a banana aroma.

Reaction Mechanism: Some of key features of the esterification mechanism are the the protonation of the carbonyl oxygen, addition of the alcohol to create a tetrahedral intermediate,

proton transfers to form water and a good leaving group, and the loss of water and deprotonation of the carbonyl oxygen to form a neutral product.

Procedure: To begin the reaction, about 5 grams of isopentyl alcohol and 8.5 mL of glacial acetic acid was added into a 50 mL round bottom flask with a stir bar. Then while slowly swirling the mixture, about 1.2 mL of concentrated sulfuric acid was added with caution. After swirling, the reflux apparatus was assembled by following the instructions and picture on page

87-88 in the Mohrig lab techniques book. After the system was assembled, the mixture was refluxed for about 60 minutes. After 60 minutes had passed, a beaker was filled with room temperature water and the reaction flask was inserted into the water without fully submerging until the reaction flask was also at room temperature. Then a ring stand was assembled and a separatory funnel was placed onto the ring. An erlenmeyer flask was placed under the separatory funnel and labeled aqueous. Then the reaction mixture was transferred to the separatory funnel and was washed with 10 mL of distilled water by following the extraction techniques on pages 152-155 in the Mohrig lab techniques book. Then the organic layer was washed with 10 mL of sodium bicarbonate. The sodium bicarbonate was added slowly while the reaction took place inside of the funnel. The funnel was swirled and placed on the ring stand several times until very little or no bubbles were observed. Then the funnel was stoppered, inverted, shaked, uninverted, unstoppered, swirled and placed back on the ring stand. Then the mixture had settled, a glass rod was placed under the separatory funnel and a drop of the bottom phase was released from the separatory funnel onto the glass rod. Then a piece of litmus paper was used to test the pH of the phase. In this point of the experiment the phase was not determined as neutral, therefore, the reaction was washed once more with sodium bicarbonate. After the layer was neutralized, the phase was separated from the funnel into the erlenmeyer flask labeled aqueous. Finally, the organic layer was washed once more with sodium chloride. After the washes were completed, the ester was transferred into a 50 mL erlenmeyer flask and magnesium sulfate was added to the flask until clumping of the magnesium sulfate wasn’t observed. While the ester was drying, the distillation apparatus was set up using the instructions and picture on page 181 in Mohrig Laboratory Techniques book. After the distillation apparatus was set up, the ester was transferred into a 25 mL round bottom flask by using glass wool and a pipette and a stir bar was added.Then after checking for proper assembly, the temperature was turned to 70 degrees celsius. Once droplets started to occur in the receiving flask, the temperature was recorded. The ester was then allowed to distill and the final boiling point temperature was recorded when reaction was almost to dryness. Before the liquid in the receiving flask was transferred to a vial, the vial was weighed. The vial was weighed again after the liquid was added to the vial. After the weight was recorded, a NMR sample was prepared by placing a small drop of the synthesized isopentyl acetate and enough solvent into the tube until it about a third of the NMR tube was full. Then a IR sample was prepared by first cleaning two salt plates with methylene chloride and drying both the plates with kim wipes. Then less then a drop was pipetted onto one of the plates and sandwiched onto the other. Then to make sure the plates were too concentrated with isopentyl acetate, the other plate was wiped with a kim wipe and sandwiched back onto the other plate.

Results and Observations: During the synthesis of the reaction in the round bottom flask, nothing was observed until the sulfuric acid was added. When the sulfuric acid was added, an odor was released from the flask. After the synthesis, the reflux began at 13:20 and when the reflux was completed at 14:15 the reaction mixture was a light brown. When the light brown mixture was added to the separatory funnel nothing was observed until the sodium bicarbonate was added to the organic layer. The sodium bicarbonate reacted with the organic layer and

bubbled. When the organic layer was washed with the sodium chloride, the organic layer became increasingly thick and yellow. After the organic layer was transferred to the erlenmeyer flask for drying, it took a great mass of magnesium sulfate before clumping was observed. When the ester was distilling, a banana odor was present and after distillation the product was clear and liquid. Reagents Table 1 Compound

Volume

MW g/mol

moles

Density g/mL

BP Celsius

Solubility at 25 Celsius

Isopentyl alcohol

6.1 mL

88.15

.056

.81

130-132

Not very soluble in water

Glacial Acetic Acid

8.9 mL

60.05

.156

1.05

117-118

Very soluble in water

130.19

.056

.87

142

Not very soluble in water

98.07

.023

1.84

337

Very soluble in water

Isopentyl Acetate Sulfuric Acid

1.2 mL

Yields and Results Table 2 Product

Actual Yield

Theoretical Yield

% Yield

Corrected Yield %

Observed BP Celsius

Literature BP Celsius

Isopentyl acetate

3.91 grams

7.8 grams

50

49.1

125

142

H NMR (300 MHz, CDCI3) of Isopentyl Acetate Table 3 Protons, Hx

Chemical Shift, ppm

Splitting Patterns

J value, Hz

Integration, cm

Relative #H’s

Ha

.789-.821

doublet of doublet

6.6

9.5

9.5/1.5= 6

Hb

1.369-1.438

quartet

7.2

3.2

3.2/1.5= 2

Hc

1.535-1.624

septet

6.9

1.5

1.5/1.5=1

Hd

1.922

singlet

0

4.6

4.6/1.5=3

He

3.954-4.000

triplet

6.9

3.1

3.1/1.5=2

IR Spectrum of Isopentyl Acetate (Neat) Table 4 Bond Vibration

Frequency (cm-1)

Intensity

C-H stretch

2959.7

strong

C=O stretch (non-conj.)

1742.6

strong

C(=O)-O stretch (acetates)

1244.2

strong

O-H in Compound B

3400

weak

Discussion and Conclusion: The Fischer Esterification of 6.1 mL of isopentyl alcohol and 8.9 mL glacial acetic acid in the presence of 1.2 mL concentrated sulfuric acid synthesized 3.91g (50% yield) of a mixture of isopentyl acetate and a small amount of impurity. NMR determined that isopentyl acetate dominated the product by 97.1%. Which allowed the % yield to be corrected to about 49.1% which is not much different to the 50% yield calculated from the theoretical and actual yields. When calculating the corrected yield, the peak at 7.2 ppm wasn’t used because it is an impurity peak for the solvent used in the NMR analysis.

In the first steps the mixture of isopentyl alcohol and glacial acetic acid remained clear until the sulfuric acid was added. The reaction was refluxed in order to boil the reaction at a constant temperature without losing solvent. The mixture turned a light brown after the reflux which could have been a result of a polymer being formed by side reactions taking place. After reflux, isopentyl acetate, water, possible isopentyl alcohol, sulfuric acid and acetic acid were left in the flask. Isopentyl acetate had to be separated from water, possible isopentyl alcohol, acetic acid and sulfuric acid. When 10 mL of water was added to the separatory funnel with the mixture, two layers were able to form due to the insolubility of isopentyl alcohol and isopentyl acetate. The acetic acid and sulfuric acid dissolved in the water because the two acids are soluble in water. After the water wash, acids were still present in the organic layer, therefore, the organic layer was washed with sodium bicarbonate. When the acids are presented with sodium bicarbonate, the acids are deprotonated and become salts which are soluble in water. The sodium bicarbonate reaction with acetic acid and sulfuric acid also produced carbon dioxide which was released as bubbles. In this specific experiment, one round of sodium bicarbonate washing wasn’t enough to dissolve the acids into the aqueous layer, therefore, another round was performed. After extraction, isopentyl acetate, possible isopentyl alcohol and water was left in the reaction mixture. The sodium chloride wash was used to extract water from the mixture and the magnesium sulfate was used to confirm that all of the water was completely removed. After the drying was performed, the isopentyl acetate and possible isopentyl alcohol were only present. Then the simple distillation was performed to purify the ester. In order to confirm that the mixture only contained isopentyl acetate, NMR and IR spectroscopy was performed. In the NMR for the synthesized product, the He signal is is shifted downfield at 3.977 ppm in comparison to if there was a presence of isopentyl alcohol in the synthesized product. The downfield shift is a confirmation of the presence of ester (COOH) due to deshielding. The NMR also confirmed the presence of isopentyl acetate by showing a singlet at about 2 ppm, which corresponded to the methyl directly attached to the carboxyl group. The presence of isopentyl acetate was also confirmed by analyzing the J values of the protons. J values for Ha-Hc and He were between 6.6 and 7.2 Hz which confirmed that those protons were close together in the structure. Two peaks on the HNMR that didn't correspond to the isopentyl acetate, which were the peaks at about 3.5 ppm due to leftover alcohol from most likely the isopentyl alcohol and 7.2 ppm due to the solvent CDCI3 used for the NMR. The CDCI3 peak wasn’t used to determine the purity of the product. The peaks on the sides of the larger H proton peaks corresponded to the spinning side bands which are caused by spinning the sample in the magnet. The spinning side bands are also not used to determine the purity of the isopentyl acetate. In the IR spectroscopy analyses, several peaks were shown. Peaks that confirmed the presence of isopentyl acetate were the signal at 1742.6 cm-1 due to the C=O vibration in an ester and 1244.2 cm-1 due to the carbonyl stretch. There was also a possible alcohol stretch present around 3400 cm-1 which is possibly due to the presence of a small amount of isopentyl alcohol. The low yield could be due to side reactions in the flask which would have occurred during reflux and removed during distillation. The low yield could also have been due to the amount of steps used in the experiment. Every time extraction, drying and distillation is performed, some product is lost which results in a lower % yield. The boiling point for the distillation was observed at 125 degrees Celsius and the literature value of isopentyl acetate was recorded at 142 degrees Celsius. Therefore, the lower boiling point observed could be due to the presence of isopentyl alcohol which boils at around 118 degrees Celsius. If errors of the experiment were corrected, there could be an increase in the amount of product recovered. For

example, measuring out solvents more carefully can prevent side reactions from occurring and it is best to use the minimal possible for a reaction to occur. Additionally, it may be beneficial to reflux the reaction for the full 75 minutes. Another error that could have affected the results of the distillation was the rapid melting of ice. In the middle of distillation, the round bottom reviving flask was removed from the ice bath in order to add more ice. This error could have affected the amount of isopentyl acetate distilled into the receiving flask. Lastly it would be beneficial to not place too much product in the NMR tube or on the IR sodium chloride plate in order to not saturate the samples. Overall, the experiment was fairly successful in which the acid catalyzed esterification of an alcohol and a carboxylic acid through reflux, extraction, drying and distillation gave fairly good yields for the isopentyl acetate. Analysis of H NMR and IR spectroscopy also confirmed the major presence of isopentyl acetate in the final product.

References 1. Wissinger, J.E. A Green Chemistry Approach Laboratory Manual. Hayden-McNeil, LLC: Plymouth, MI, 2018, pp, 59-62. 2.

https://pubchem.ncbi.nlm.nih.gov...

Similar Free PDFs

Synthesis of Isopentyl Acetate

- 7 Pages

Synthesis of Isopentyl Acetate

- 4 Pages

CCA - Ksp of silver acetate

- 3 Pages

SYNTHESIS OF DIMETHYL ETHER

- 54 Pages

Synthesis of Sudan-1

- 4 Pages

The synthesis of Ibuprofen

- 4 Pages

Synthesis of methyl orange

- 9 Pages

Synthesis of Aspirin

- 10 Pages

Synthesis of Acetanilide

- 5 Pages

Synthesis of p-nitroacetanilide

- 6 Pages

Synthesis of Flavonol 2

- 13 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu