Lab 8 - Lecture notes l8 PDF

| Title | Lab 8 - Lecture notes l8 |

|---|---|

| Author | Parth Patel |

| Course | Organic Chemistry Laboratory I |

| Institution | University of Illinois at Chicago |

| Pages | 12 |

| File Size | 423.1 KB |

| File Type | |

| Total Downloads | 72 |

| Total Views | 145 |

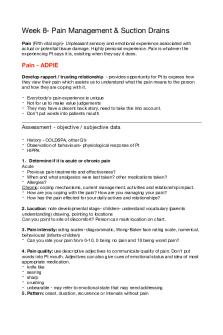

Summary

Lecture reading from TA...

Description

Lab 8: Preparation of Alkenes by E1 and E2 Elimination Reactions. Bayer and Bromine Tests for Unsaturation. Milan Patel March 30, 2016 Methods and Background The main purpose of this lab was to prepare distribution of alkenes by E1 and E2 reactions. Thus, the objectives of this experiment was to prepare 2-methyl-2-butene and 2-methyl-1-butene by reacting 2-methyl-2-butanol and sulfuric acid as elimination 1 reaction and reacting 2-chloro-2methylbutane with potassium hydroxide as elimination 2 reactions. The structures of the products are shown in figure 1. The 2-Methyl-1-butene is the minor product of the reactions. Whereas, 2Methyl-2-butene is the major product. This is because major product is the more substituted product which makes it more stable compared to the minor product. That is why we produced more of 2-Methyl-2-butene compared to 2-Methyl-1-butene.

Figure 1: 2-Methyl-1-Butene (Left) and 2-Methyl-2-Butene (Right) Furthermore, the fractional distillation and heat reflux were used to isolate the product. Fractional distillation was preferred due to very small boiling point difference (7.7 oC which is less than 50 oC) between two desired products. Unlike simple distillation, fractional distillation yields a higher amount of product since the surface area inside the hempel column has been increased because of raschig rings. Raschig rings increase the surface area of the column, hence increasing the number of theoretical plates. In fractional distillation, the solution is constantly recondensing and re-evaporating, which increases the mole concentration of the distilling product according to Raoult’s Law. Therefore, since fractional distillation increases the mole concentration with each cycle of condensing and evaporating the final distilled product is much more concentrated than it would be in simple distillation. The purpose behind heat reflux was to reduce the time require for the reaction to go completion. When performing the heat reflux, a reaction mixture is heated at its boiling point in a flask equipped with a reflux condenser to allow continuous return of the volatile materials to the flask. While the heat reflux is running, there is no solvent or reactant removed or lost. Thus, the reaction can be conducted at higher temperatures and it can be completed within less amount of time. Ultimately, Baeyer and bromine tests were performed to classify the products. In addition, the Gas Chromatography analysis was also done in order to find the percent yield for each isolated products. Elimination reactions are one of the most common ways to produce carbon-carbon double bonds. These types of reactions can occur by either functional group transformation, where a carbonhalogen single bond is converted to the carbon-carbon double bond, or by dehydration, where the

carbon-carbon double bond is formed by the removal of elements of water from an alcohol. The presence of an alkyl halide in a molecule often causes an inductive effect, increasing the acidity of hydrogen atoms on adjacent carbons. A carbon-carbon double bond is formed when the βhydrogen is removed and the halogen leaves. The β-hydrogen is positioned at anti-periplanar to the halogen, 180o from each other. The presence of a strong base can trigger this reaction, since it will remove one of the acidic protons. Furthermore, since the removal of the proton and the loss of the leaving group occur in the same step, this type of reaction is referred to as an E2 reaction. E2 reactions are also referred to as bimolecular reactions. The the rate law depends on the base and substrate as shown in the figure 2.

Figure 2: E2 Reaction Mechanism An E2 reaction readily competes with SN2 reactions. One way to favor elimination reactions is to increase the degree of substitution of the carbon. A tertiary carbon is more hindered than a primary carbon, which will hinder the backside attack of the nucleophile, so in this case elimination will favor. A tertiary carbon will favor elimination and a primary carbon will favor substitution. Another way to experimentally favor elimination is by adding heat to the reaction, which causes the base to act less like a nucleophile. That is the reason behind performing the heat reflux for an hour. This, favors elimination reaction over the substitution reaction. As shown in the figure 3, the presence of an alcohol group causes the elimination to occur in a different way, which changes the environment required for the reaction to occur compared to that of an E2 mechanism. A hydroxyl group is a poor leaving group which requires additional step of making it good leaving group. The nonbonding lone pairs of electrons on the oxygen atom of the hydroxyl group act as Lewis bases. Thus, the oxygen atom can be protonated to form water, which is an excellent leaving group. In the presence of a base, the carbon-carbon double bond can then be formed by the deprotonation of a β-carbon.

Figure 3: E1 Dehydration Reaction Mechanism of Alcohols Each of the two reactions produces two products, the Zaitsev’s product and the Hoffman product. The Zaitsev’s product is observed when the carbon-carbon double bond forms on the more substituted carbon. Hoffman product is observed when the carbon-carbon double bond forms on the least substituted carbon. Most reactions will have Zaitsev’s product as the major product and Hoffman product as the minor product. The reason for this is alkene stability is that since Zaitsev’s product forms on the more substituted carbon it has higher stability than Hoffman product. There are certain exceptions to this rule and the Hoffman product will be the major product. When a base is too large or when the carbon is sterically hindered by other large functional groups present, Hoffman product will be the major product. In order to classify the products, two classification tests were used. One was the Baeyer Test and the other was Bromine Test. Baeyer Test checks for the unsaturation. The product reacts with potassium permanganate and in the presence of carbon-carbon double bonds the products that are formed are a vicinal diol and manganese dioxide. This reaction is a syn addition. In the presence of C=C double bonds, potassium permanganate oxidizes the double bond and forms diols, this results in the change of color from purple to brown. The change in color is a positive test for unsaturation. Figure 4 represents the mechanism for this reaction. Nonetheless the additional test was required to classify the products because in the Baeyer test, the permanganate also oxidizes other functional groups such as aldehydes, therefore this test is not selective for carbon-carbon multiple bonds. Thus, Bromine test was done as well to classify the alkene products.

Figure 4: Baeyer Test: Oxidation of Double Dond Bromine test on the other hand is an addition of molecular bromine (Br2) across a double or triple bond. This reaction is anti-addition. A cyclic bromonium ion is the intermediate followed by attack of the ion by bromide to form a vicinal dihalide. Bromine is orange-red in color and vicinal dihalide is colorless. Hence, the disappearance of the orange/red color is the positive test for the bromine test. In the absence of carbon-carbon double bond, the orange color will not disappear. Figure 5 represents the mechanism of the Bromine Test.

Figure 5: Bromine Test: Addition across Double Bond Additionally, Gas Chromatography was performed on the collected fractions of E1 and E2 reactions. The purpose of GC was to calculate the molar percentages of minor and major products in order to find out the percent yield and the selectivity of the better elimination reaction. The overall results of this lab indicates that we were able to isolate 2-methyl-2-butene and 2methyl-1-bunete by E1 and E2 reactions. The E1 yielded 57.03% of the total product and E2 yielded 64.14%. Molar percentages were also calculated for each the minor product and the major product for the E1 and E2 reactions. The molar percentage of the major product was higher for E1 which suggests that E1 reactions are more selective than E2 reactions. Two classification tests were also carried out, the bromine test was positive for both E1 and E2 reactions and the Baeyer test was also positive for E2 and E1 reactions. Experimental Procedure Part I: Synthesis of 2-Methyl-1-Butene and 2-Methyl-2-Butene E2 Reaction Procedure

First of all, 6.04 g of potassium hydroxide (KOH) and 60.4 mL of 1-Propanol was measured out and transferred to a round-bottom flask. Then, 1-2 boiling stones were added to the flask. All of the potassium hydroxide was melted by heating the mixture gently. After dissolution of the base,

the flask was cooled to room temperature and placed in the ice bath. 5.22 g of 2-chloro-2-methyl-butane was slowly added to the mixture. A heat reflux apparatus was set up as shown in figure 6 and also all of the joints were greased to avoid freezing from the caustic KOH solution. The hempel column was filled with raschig rings and the reaction was heated under reflux for 1 hour. While waiting for the reflux to finish, E1 reaction was performed as described below. After 1 hour, the reaction was allowed to cool below its boiling point and then fractional apparatus was set up as shown in figure 6 and all the joints were greased as well. Then, 25mL receiving flask was pre-weighed and then the reaction was distilled and only one fraction was collected until the boiling point of the mixture reached 45 oC. The receiving flask was kept in an ice bath at all times. The final product was weighted and GC analysis was performed. The percent yield was also calculated and the classification tests were done. The observations and results were recorded. Figure 6: Reflux Apparatus (Left) and Fractional Distillation Apparatus (Right) E1 Reaction Procedure This reaction was performed while waiting for 1 hour of reflux during E2 reaction. First of all, 2 mL of 2-methyl-2-butanol was measured and transferred into a 25 mL of round bottom flask. Then, 10 mL of 6 M sulfuric acid was added to the reaction. Fractional distillation apparatus was assembled as shown in figure 6, and the Hempel column was filled with raschig rings. A preweighed flask was used as the receiving flask and was kept in an ice bath while collecting the distillate. The mixture was heated and distilled till the temperature reached about 45oC. The final product was weighed and GC analysis was carried out. The product mixture was kept in an ice bath at all times. The observations and calculations were recorded. Part II: Analysis of Product Distribution by Gas Chromatography

A gas chromatography graphs were obtained and printed out for both E1 and E2 reaction mixtures. The molar percentages of 2-methyl-1-butene and 2-methyl-2-butene (alkenes) in each fractions were calculated. These molar percentages were used to calculate the percent yield. Part III: Confirmation of Alkene Formation by Classification Tests Baeyer Test: Three test tubes were prepared by adding 1 mL of 95% ethanol to each. In a first test tube, 1-2 drops of the product mixture from the E1 reaction were added. In second test-tube, 1-2 drops of the product mixture from the E2 reaction were added and into the third test tube nothing was added. In all test tubes, solution of 0.1 M KMnO4 was added drop wise. The drops were counted until the purple color persisted, and the color change and other observations were recorded into the data table. Bromine Test: Three test tubes were prepared by adding 1 mL of methylene chloride to each. In a first test tube, 1-2 drops of the product mixture from the E1 reaction were added. In second test-tube, 1-2 drops of the product mixture from the E2 reaction were added and into the third test tube nothing was added. In all test tubes, solution of 0.1 M Br2 in dichloromethane was added drop wise. The drops were counted until the light orange color just persisted. The color change and other observations were recorded into the data table. Data Acquisition/Presentation Reaction Tables: Reagents Table 1: Elimination 1 Compound

Molecular Weight (g/mol)

Density (g/mL) Or Molarity (mmol/mL)

Rxn Weight (g) Or Volume (mL)

mmol

Equivalents

2-Methyl-2butanol

88.15

0.805 g/mL

2.0 mL

18.26

1.0

Sulfuric Acid

98.08

6M

10.0 mL

60.0

3.28

Table 2: Elimination 2 Compound

Molecular Weight(g/mol)

Density (g/mL)

Rxn Weight (g) Or Volume (mL)

mmol

Equivalents

2-chloro2methylbutane Potassium Hydroxide 1-Propanol

106.59

0.866 g/mL

6.03 mL

48.97

1.0

56.11

N/A

6.04 g

107.6

2.2

60.10

0.804 g/mL

60.4 mL

808.0

16.5

For E1 and E2 reaction the mmol of each reactant was calculated by converting the mLgramsmolmmol. 1mol=1000mmol and the grams of each reagent were obtained from the mL used and the density provided. The amount of potassium hydroxide and 1-propanol to be used was calculated by using the equivalents that were given. The grams were obtained from the density provided and the moles were obtained from the molecular weight and grams of the reagent. Calculations: Molecular Percentage: Percent yield:

Mol % of comp .1=

Area 1 × ×100 Area 1+ Area 2

Actual Yield ×100 Theoretical Yield

Mass of minor/major product in the actual yield:

Molar Percentage × mass ( g ) of actual yield 100

Elimination 1: Molar Percentage Mol % 2−methyl−1− butene=

111.2 s∗ mv × 100 ≈ 9.36 % 111.2s∗ mv +1077 s∗mv

Mol % 2−methyl−2− butene=

1077 s∗ mv × 100 ≈ 90.64 % 111.2s∗ mv +1077 s∗mv

Theoretical Yield 2 mL of alchohol ×

1 mol butene 70.13 g butene 0.805 g alchohol 1mol alchohol × × × = 1 mL alchohol 88.15 g alchohol 1mol alcohol 1mol butene

1.28g Butene

*In this equation alcohol = 2-methyl-2-butanol, and Butene= 2-methyl- 2-butene Basic stoichiometry was used to calculate the theoretical yield Actual Yield

(Mass (g) of pre-weighed flask + product) – (Mass (g) of pre-weighed flask) 43.02 g – 42.29 g = 0.73 g 2-methyl-2-butene Percent Yield 0.73 g ×100 = 57.03% 1.28 g Mass of minor/major product in the actual yield: Minor Product 9.36 × 0.73 g=0.068 g Minor Product 100 Major Product 90.64 × 0.73 g=0.66 g Major Product 100 Elimination 2: Molar Percentage Mol % 2−methyl−1− butene=

249.4 s∗mv ×100 ≈ 38.95 % 249.4 s∗mv + 390.9 s∗mv

Mol % 2−methyl−2− butene=

390.9 s∗mv ×100 ≈ 61.05 % 249.4 s∗mv + 390.9 s∗mv

Theoretical Yield 5.22 g of butane ×

1 mol butene 70.13 g butene 1 mol butane × × = 3.43 g butene 1 mol butene 106.59 g butane 1 mol alcohol

*In this equation butane= 2-chloro-2methylbutane, and Butene= 2-methyl- 2-butene Basic stoichiometry was used to calculate the theoretical yield. Actual Yield (Mass (g) of pre-weighed flask + product) – (Mass (g) of pre-weighed flask)

60.97 g -58.77 g = 2.20 g 2-methyl-2-butene Percent Yield 2.20 g ×100 = 64.14% 3.43 g Mass of minor/major product in the actual yield: Minor Product 38.95 ×2.20 g=0.8569 g Minor Product 100 Major Product 61.05 ×2.20 g=1.3431 g Major Product 100 Table 3: Summery of Overall Results from the Experiment Reaction Product Name

Elimination 1 (H2SO4 + 2-methyl-2-butanol) 2-methyl-1-butene 2-methyl-2-butene

Elimination 2 (KOH + 2-chloro-2-methylbutane) 2-methyl-1-butene 2-methyl-2-butene

0.73 g

2.20 g

Grams of Total Product Yield (Molecular Percentage)

9.36%

90.64%

38.95%

61.05%

Grams of each product Boiling Point

0.068 g

0.66 g

0.8569 g

0.1.3431 g

31.3 oC

39 oC

31.3 oC

39 oC

Baeyer Test

Positive Color Changed from Purple to Brown Positive Color Changed from Orange to

Positive Color Changed from Purple to Brown Positive Color Changed from Orange to

Positive Color Changed from Purple to Brown Positive Color Changed from Orange to

Positive Color Changed from Purple to Brown Positive Color Changed from Orange to

Bromine Test

Clear Percent Yield

Clear

Clear

57.03%

Clear 64.14%

Table 4: Mass of Product Product

Mass (g) Pre-Weighed Flask

Final Mass of Product (g)

42.29 g

Mass (g) of PreWeighed Flask + Products 43.02 g

Elimination 1 Elimination 2

58.77 g

60.97 g

2.20 g

0.73 g

Table 5: Bayer and Bromine Test Results Test Type

Test Tube 1 (E1 Product)

Test Tube 2 (E2 Product)

Test Tube 3 (Nothing)

Baeyer

Color change from purple to brown

Color change from purple to brown

No color change, solution stayed purple

Bromine

Color change from orange to clear

Color change from orange to clear

No color change, solution stayed orange

Conclusions The purpose of this experiment was to prepare 2-methyl-2-butene and 2-methyl-1-butene by reacting 2-methyl-2-butanol and sulfuric acid as elimination 1 reaction and reacting 2-chloro-2methylbutane with potassium hydroxide (KOH) as elimination 2 reaction. Classification tests such as bromine test and Baeyer test were also performed in order to figure out if the reaction went to completion and produced alkenes. GC analysis was also done after isolating the product. GC analysis let us calculate the molar percentages of major and minor products. 2-methyl-2butene considered as major product whereas 2-methyl-1-butene is the minor product because we get more of 2-methyl-2-butene than 2-methyl-1-butene in both reactions. The percent yield for elimination 1 reaction was 57.03% and for elimination 2 was 64.14%. The reason for the low percent yield could’ve been the fact that the equipment wasn’t set up correctly. The compounds are highly volatile and they have relatively low boiling points. Thus, they could be evaporate quickly if we had failed to follow specific directions such as keeping the product in the ice bath at all times, putting the stopper on the receiving flask when it was not attached to the distillation apparatus. Other reason after having low percent yield could be that we could had a leak in the distillation apparatus which would had affected our results.

According to the GC analysis, E1 is more selective than E2. As it can be seen from the graphs that the amount of major product is higher in E1 than it is in E2, based on this data we can say that E1 is more selective than E2. Molar percentages of the minor and major product were also calculated using the area under the peaks. These molar percentages were then used to calculate the grams of each product in each reaction. While solving for the molar percentages the correction factors weren’t needed for the calculations because of the similarity of polarity and molar masses of the products. Furthermore, data showed that the gram of the major product was always higher than that of the minor product. Additionally, the graphs showed that the retention time for the minor product was less than the retention time of the major product. This was due to the fact that the major product is the product with most substituents and the minor product has the less substituents. Thus, the major product is more stable than minor product. As a result, the major product has higher boiling point than minor products. That is why minor product is more volatile and had lower retention tim...

Similar Free PDFs

Lab 8 - Lecture notes l8

- 12 Pages

PS2030 - L8 - Lecture notes 8

- 9 Pages

L8 - Notes

- 2 Pages

Aldol lab - Lecture notes 8

- 4 Pages

8 - Lecture notes 8

- 21 Pages

8 - Lecture notes 8

- 21 Pages

8 Midwifery - Lecture notes 8

- 3 Pages

Taxation 8 - Lecture notes 8

- 2 Pages

Week 8 - Lecture notes 8

- 6 Pages

Dox 8 - Lecture notes 8

- 21 Pages

Lesson 8 - Lecture notes 8

- 2 Pages

Assignment 8 - Lecture notes 8

- 4 Pages

Week 8 - Lecture notes 8

- 23 Pages

WEEK 8 - Lecture notes 8

- 10 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu