Evaporation loss of Hydrocarbon in Handling Petroleum PDF

| Title | Evaporation loss of Hydrocarbon in Handling Petroleum |

|---|---|

| Author | Juun Pyo |

| Pages | 8 |

| File Size | 495 KB |

| File Type | |

| Total Downloads | 195 |

| Total Views | 915 |

Summary

132 Evaporation Loss of Hydrocarbon in Handling Petroleum* by Ikutoshi Matsumura** Summary: Evaporation lossesof hydrocarbonsfrom various sources, such as refinery plants, oil terminals and gas stations, were studied. A correlation involvingthe volumeof discharged gas, temperatureand hydrocarbonconc...

Description

132

Evaporation

Loss of Hydrocarbon by Ikutoshi

in Handling

Petroleum*

Matsumura**

Summary: Evaporation lossesof hydrocarbonsfrom various sources, such as refinery plants, oil terminals and gas stations, were studied. A correlation involvingthe volumeof discharged gas, temperatureand hydrocarbonconcentrationwas derivedfor crude oil and petroleumproducts. These gas emission sourceswere classified according to their mode of evaporation. As a result, hydrocarbonemissionfactors in terms of annual mean value were obtainedfor various emissionsources,such as cone and floating roof tanks, loading tankers, tank trucks and gas stations; and also the hydrocarbonemissionfactorsfar crudeoil and suchpetroleumproductsas naphtha, gasoline, kerosene,diesel oil and fuel oil. The hydrocarbonemissionfactors obtained in this study were smaller than thosepresented by the U. S. EPA. The calculated hydrocarbonemissionfactor for loading a tanker which was calculatedfor the first time, was less than 1/5 of that for loading a tank truck. The hydrocarbonemission factor for loading various kinds of vesselswith keroseneand diesel oil was about 1/500 of that for loading the same types of vesselswith gasoline. 1

2

Introduction

In Japan, photochemical smog began to appear several years ago, but its causes are still not clearly known. As a preventive measure for such photochemical smog, it seems necessary to prevent discharge of hydrocarbons which were regarded as one of the major causes. But quantitative measurements of hydrocarbons from stationary sources had not been made in Japan. In the U. S. A., API (American Petroleum Institute) investigated evaporation losses of hydrocarbons from cone roof tanks1),2), floating roof tanks3), gas stations4) and transportation facilities5),6) from 1957 to 1963, and the U. S. EPA7) (Environmental Protection Agency) calculated a HC (Hydrocarbon) emission factor based on the results of API investigation. But the HC emission factor proposed by the U. S. EPA would not necessarily be applicable to the cases in Japan, because the climate and the surrounding conditions in Japan are different from those in the U. S. A., and the object facilities for the EPA investigation are also different. Therefore, in this paper a study of evaporation losses of hydrocarbons from refinery plants, oil terminals and gas stations is presented. HC emission factors were obtained for storage and transport of crude oil and petroleum products such as naphtha, gasoline, kerosene, diesel oil and fuel oil. * **

Received July 16, 1974 Nippon Oil Co ., Ltd. (3-12, 1-chome, bashi, Minato-ku, Tokyo 105)

Method

2.1

and

Investigated

Facilities

Method

In order to calculate the HC emission factor, the volume of discharged gas and HC concentration of the gas were measured for each source. In measuring the gas volume, the gas outlet such as a breathing valve and hatch were closed so that discharging gas could be conducted to an anemometer, which had an inlet of 4 in. diameter and was capable of measuring a gas velocity as low as 0.2 M/S. The

gas

volume

the cross sectional the velocity of the

was

obtained

by

multiplying

area of the anemometer by gas stream. The gas sampled

in a 100ml syringe at the gas outlet was brought to the laboratory and analyzed by gas chromatography

with

gaseous HC ard normal with

6

FID.

The

component paraffin,

carbons

were

equivalents and those and so on. 2.2

Investigated

concentration

of

each

was calculated as standthat is, all hydrocarbons calculated

with

5 carbons

as

n-hexane

as n-pentane

Facilities

Investigation was carried out throughout 1973 at refineries, oil terminals and gas stations located mainly in Yokohama but also those located in various other places in Japan. HC emissions from following facilities were investigated. (1)

Floating-roof

tank:

nominal

capacity

3,000

∼100,000kl

Nishi-shin-

(2)

Cone-roof

tank:

nominal

capacity

1,300∼

18,000kl

Bulletin of The Japan Petroleum Institute

Matsumura:

Evaporation

Loss of Hydrocarbon

in Handling

Petroleum

133

(3) Underground tank at a gas station: nominal capacity 10kl (4)

Tanker:

loading

(5) Tank truck: (6)

Tank

(7)

Automobile:

3

car:

Results

capacity

1,800∼5,000kl

loading capacity 2kl/l hatch loading

capacity

gasoline

and

40∼58kl

tank

capacity

40∼60l

Discussion

3.1 Evaporation Loss from Storage Tanks To calculate the quantity of HC emission from a storage

tank,

the

gas

sources

were

according to their mode of evaporation concentrations, and the HC emission breathing and were obtained. 3.1.1

working

Cone

Roof

latile

Petroleum

losses

Tank

classified and HC factors for

of various

for

Storage

tanks of

Fig.

1

Discharged Gas Volume vs. Tank for Breathing of Cone Roof Tanks

Capacity

Fig.

2

HC Concentration of Discharged Gas of Cone Roof Tanks vs. Atmospheric Temperature

Vo-

(1) Breathing Loss Factors breathing

affecting

the

from

cone

a

of oil, temperature HC emission factor relation emitted.

between

quantities roof

of emission

tank

and tank was obtained

these

factors

are

the

by kind

capacity. The from the cor-

and

the

quantities

(a) Seasonal variation of discharged gas volume and discharging time from tanks From the investigation of a crude oil tank having a capacity of 18,000kl, it was noticed that discharge and intake of the gas were caused by temperature difference during the day, and it was found that the emission of hydrocarbons was accompanied by the discharge of the gas in the tank. Therefore, the discharged gas volume from the tank was measured for a period of one year. The results obtained were in a range from 80m3/ hr to 150m3/hr and were not depending on the seasons. It is concluded that the amount of discharged gas by breathing depends on the daily temperature difference and not on the average temperature. The average daily temperature difference in

winter.

tank in

be

in

The

with

and

pointed

discharged

its HC

is 7℃ discharge

temperature

summer

perature, depends

Yokohama

out

of increase

7∼8hrs

that

in

in

HC

gas depends

summer the

gas took

winter.

and

on

the atmospheric

and that the amount on both the discharged

should

of

the tem-

of HC emission gas volume and

concentration.

(b) Tank capacity and discharged gas volume The correlation between tank capacity, V (kl), and discharged gas volume, Q (m3/hr), by breathing is shown in Fig. 1. An empirical equation Volume

16, No. 2, November

1974

Q=K1V2/3 where

K1 is the

constant

(2) depending

on

oil pro-

perties as follows; Gasoline: K1G=0.20 Crude oil: K1C=0.16 Light naphtha: K1L=0.21

the

10∼11hrs

concentration

Thus

9℃

from

It

between Q and V is obtained as follows;

(c)

HC concentration of the discharged gas

HC

concentration

a cone

roof tank

during

the

The the

day,

although

correlation

perature

T

From

between

(℃)

discharged

and gas

Fig.

concentration is expressed

of the

discharged

by breathing

the

C (%)

2, the

it changes the HC

constant

in

between

and the atmospheric as follows;

K2 is the

seasonally. tem-

concentration

is shown

correlation

from

constant

atmospheric

LogC=0.017T+LogK2 C=K2 exp (0.039T) where

gas

is almost

depending

Fig.

the

of 2.

HC

temperature

(3) (4) on oil pro-

Matsumura:

134

Table

1

HC

Vapor

Composition

Pressure Weight of

of

and Each

Discharged

Mean Kind

Gas,

Loss of

Reid

Molecular of Oil

Fig.

3

Table

Tank Capacity vs. HC Emission Breathing of Cone Roof Tanks

2

Emission Roof

perties

Evaporation

Factor Tank

of

Breathing

Factor

from

a

for

Cone

(kg/day・tank)

as follows;

Gasoline: Crude oil: Light

K2G=16 K2C=12

naphtha:

K2L=21

(d)

HC emission factor of breathing from cone roof tanks After multiplying the discharged gas volume shown in equation (2) by the HC concentration shown in equation (4), and converting the concentration unit by using the mean molecular weight of HC, the HC emission in weight per unit time is obtained as shown in Table 1. Thus,

where

the

following

equation

F: HC emission in weight per unit time (kg/hr) V: Tank capacity (kl) T:

Atmospheric

M:

Mean

temperature

molecular

discharged t:

K1, K2: The annual time day

of the

depending

between

average

discharged

factor

the

annual and gas

factors

of breathing

shown

in Table

tank

capacity

in Fig.

breathing

average

30℃.

loss from

gas

(℃)

Fig.

4

Some

in daytime

per

temperature HC

Q=1+0.16P(m3/kl

and

3, where

of

Discharged Gas Volume vs. Reid sure, for Filling one Kiloliter Product in Cone Roof Tanks

Vapor PresPetroleum

ferent Reid vapor pressures P (kg/cm2), are shown in Fig. 4. The relation between P and Q is expressed as follows;

on oil properties

temperature

average

annual is

discharged

is shown

atmospheric

is 18℃,

(℃)

of HC in the

gas

Constants

emission

is 9hrs.,

weight

Temperature

correlation

the HC

is derived

filling)

(6)

Multiplying the HG concentration in equation (4) by the discharged gas volume in equation (6), the HG emission factor of filling a cone roof tank is expressed as follows;

emission

a cone roof tank

are

2.

(2) Filling Loss When a cone roof tank is filled with one kiloliter of petroleum, more than one cubic meter of gas is discharged, because of evaporation of the petroleum. The discharged gas volumes Q (m3/kl) for filling one kiloliter of petroleums having dif-

where

The

F: HC emission factor of filling a cone roof tank (kg/kl filling) P: Reid vapor pressure (kg/cm2) T, M, t, K2: Same as equation (5)

correlation

between

atmospheric

temperature

Bulletin of The Japan Petroleum Institute

Hydrocarbon

in Handling

135

Petroleum

under

the following Storing

conditions;

product:

Light

naphtha

Reid vapor pressure: Atmospheric

temperature:

Surface

the

the

roof:

50℃

pontoon: the

under

38℃,

the

the

beneath

temperature to

of

under

Temperature

rises

32.8℃

temperature

Temperature

As

0.95kg/cm2

the

31℃

roof:

40℃

pontoon

average

occasionally

rate

of

emission

of

HC becomes 50m3/hr. Secondly a gasoline with 0.68kg/cm2 Reid vapor pressure was measured under the following conditions; Surface

Fig.

5

HC Emission Factor vs. Atmospheric rature for Filling Cone Roof Tanks

Table

3

HC Emission Factors Cone Roof Tank

a

temperature

average

of

18℃

temperature

of

3 shows

and the

30℃.

Table

3.1.2

Floating

Roof

the

Volatile

Petroleum

for

the

results

Tanks

of

of

and easily

is emitted,

and

ノ

annual

a

by direct

evaporated.

discharged

conduction

Thus

through

of

HC vapor a breathing

summer,

emitted

on the

emission.

quantities a floating

(1)

The

petroleum

wall

remaining is emitted.

temperature

of HC

of

emitted.

emission

crease

in

Volume

15, No. 2, November

the

was

the

10∼15m3/hr

temperature

roof,

the

tem-

and the atmospheric with regard to the It was

vapor

the

45℃,

tempcrature

the

of

average

HC

there of

rate

emission

are

the

44

roof

under 1974

found for

the

that 1℃

HC in-

pontoon

60℃

of for

15m3/hr

of

the

of

gas

is 20,600

days

is

above

when

the

50℃

in

the

the for

roof

is over

temperature

the

average

60℃ of

rate

of

the gas

テ

The

annual

kg/year・tank, surface a

Breathing Loss the

amount where

temperature

gas,

サ

The

of these two cases from determined.

perature under the pontoon temperature were measured amount

internal

vapor

of HC emissions roof tank were

First,

65℃,

to

Gasoline tank (Reid vapor pressure 0.68 kg/cm2, tank capacity 5,000kl) The HC emission factor, 75kg/day.tank, was obtained by using the following values: 100 % for HC concentration, 68 for the mean molecular weight of HC, 2hrs/day for the period when in

of the HC

for for

temperature

of the

part and

50℃.

to

year.

roof lowers

evaporates

roof

the

50℃

50m3/hr

kg/year・tank,

surface

wall

40

サ

the

tank is exposed.

60

emission.

valve. On the other hand, when withdrawing the petroleum from a floating roof tank, the and

roof

pontoon

(b)

the roof is heated

solar heat

summer, gas,

surface

Storage

When storing petroleums such as naphtha, gasoline etc. in a floating roof tank, the petroleum beneath

in

emitted

The

gas

obtained.

for

beneath

50℃

annual

discharged

Temperature

the

the

(a) Light naphtha tank (Reid vapor pressure 0.95kg/cm2, tank capacity 5,000kl) The HC emission factor, 468kg/day.tank, was obtained by using the following values: 100% for HC concentration, 62 for the mean molecular weight of HC, 4hrs/day for the period when the surface temperature of the roof is above

and HC emission factor in equation (7) is shown in Fig. 5. From Fig. 5, average HC emission factors were obtained for annual average atmospheric

of

under

The average rate of HC emission was 15m3/hr. Calculation of HC emission factor was made using the above data.

Tempe-

of Filling

temperature

Temperature

amount

of

where

there

temperature

of

the

HC

emission

are

30

roof

days

is above

is 2,230 when 6...

Similar Free PDFs

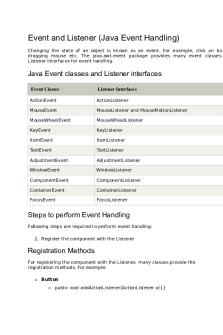

Event Handling IN JAVA

- 6 Pages

The formation of petroleum

- 8 Pages

METHODS OF HANDLING DEADLOCK

- 2 Pages

Advantages of exception handling

- 2 Pages

Sample schedule of loss

- 2 Pages

Affidavit of Loss - Marave

- 1 Pages

Chapter 10 - Evaporation

- 28 Pages

Petroleum System

- 22 Pages

Petroleum - motes

- 1 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu