Sitxfsa 002 - A01 - Participate in safe food handling practices PDF

| Title | Sitxfsa 002 - A01 - Participate in safe food handling practices |

|---|---|

| Author | Professor Bunny |

| Course | Participate in safe food handling practices |

| Institution | Central Queensland University |

| Pages | 18 |

| File Size | 348.4 KB |

| File Type | |

| Total Downloads | 77 |

| Total Views | 152 |

Summary

Download Sitxfsa 002 - A01 - Participate in safe food handling practices PDF

Description

SIT40516 Certificate IV in Commercial Cookery

SITXFSA002 Participate in safe food handling practices ASSESSMENT 1: Assignment Student’s Name Student No Student Declaration

I declare that the work submitted is my own. It has not been copied or plagiarised from any other person or source.

Student’s Signature Date Submitted

1

You have been appointed as chef de partie in the prestigious Futura Beach Hotel which will open its door to the public late next month.

In order to conform to the latest requirements for food safety you are required to write a set of Standard Operating Procedures (SOPs) to meet all requirements outlined in the current legislation. You will also need to provide a reference manual for all relevant staff.

1. A reference to the current legislation. Where can this be accessed and what are the key requirements relating to (access this information on the website for specific details) : a. Food safety standards :

Businesses that serve or process potentially hazardous food for service to

vulnerable people. This includes businesses providing food to hospital patients, aged care residents and children in child care centers.

Delivered meal organisations that prepare food for delivery to vulnerable

people.

Seafood businesses that engage in the primary production or processing of

seafood.

Businesses producing manufactured and fermented meats.

All other food businesses must comply with food standards determined by

their local council.

b. Food safety plan :a. Systematically identify the potential hazards that may be reasonably expected to occur in all food handling operations of the food business; b. Identify where, in a food handling operation, each hazard identified under paragraph (a) can be controlled and the means of control; c. Provide for the systematic monitoring of those controls; d. Provide for appropriate corrective action when that hazard, or each of those hazards, is found not to be under control; e. Provide for the regular review of the program by the food business to ensure its adequacy; and f. Provide for appropriate records to be made and kept by the food business demonstrating action taken in relation to, or in compliance with, the food safety program

c. Documentation :

Record of goods received

Cool room and Freezer temperature record

Cleaning schedule

Health Monitoring

Cooling-Heating log

Internal audit checklist

Training register etc

d. Danger Zone :The temperature range where bacteria multiplies rapidly between +5 C and +60 C. Items to be cooled should be placed in shallow trays on shelves within the fridge, to allow air circulation. Alternatively, food items may be quickly cooled using a blast chiller or freezer. It is also important to thaw food correctly to avoid the danger zone. Food for thawing should be placed on trays which are covered and clearly labelled. The trays should be placed on a low shelf in the cool room so that any drips or juices do not contaminate other items. Never run hot/warm water over food to thaw it! When reheating food, you must ensure that it rapidly reaches 60°C or more. Ideally all food items would be brought to the boiling point for a short period of time. If you let the food remain in the danger zone for very long, the microorganisms that have been dormant will quickly begin to multiply. The longer food is left in the danger zone, the higher the chance of poisoning your customers.

e. Critical Limits and Time Frames:Critical limits – maximum or minimum levels which ensure safety of the product. For example, if the number of bacteria in a sample is below a certain level, then the product is deemed acceptable; if the number of bacteria is above that level, the product is deemed unacceptable. Minimum internal temperatures are critical limits for cooking. Do not leave food in the danger zone (between 5 and 60°C) for more than 1 hour. To maintain shelf life, cook-chill items have to be cooked at safe temperatures and then chilled within specific timeframes. The food safety standards require the internal temperature of food to be reduced from 60°C to 21°C in a

maximum of 2 hours and from 21°C to 5°C within a further maximum period of 4 hours. Blast chillers or freezers are used for this process in commercial situations.

f. The provisions for legislation and provisions at local government level In Australia, local councils are in charge of enforcing building codes, supervising safe food handling and conducting random inspections of food premises. They can also establish grading systems for premises that comply with the food safety standards. The Food Acts outline basic hygiene and temperature requirements for food handling. They also detail the role of Environmental Health Officers (EHOs). The EHOs play an important role in keeping our industry safe for both customers and workers. EHOs, commonly referred to as Health Inspectors, have wide-reaching powers to conduct checks of premises, compliance with building codes and adherence to safe food handling practices.

g. The implications for failing to comply with legislation Failure to comply with food legislation can result in breach notices, fines and court proceedings.

2. The meaning of HACCP, the seven principles and the required procedures for each principle. Hazard Analysis of Critical Control Points (HACCP) is a system that originated in the USA to prevent food poisoning of astronauts whilst in space. It incorporates general hygiene requirements into the daily operational processes of an establishment and is used to minimise the risk of food poisoning, by analysing possible points of contamination. Good mise en place and workflow will help to perform the required duties of monitoring and record keeping.

1. Hazard analysis – hazards are any biological, chemical or physical property which could cause a food safety problem. Hazards can occur at any part of the food production pathway. Hazard analysis involves identifying and assessing the seriousness and likelihood of the hazard occurring.

2. Critical control point – a point, step or procedure at which control can be applied so the hazard can be prevented, eliminated or reduced to an acceptable level.

3. Critical limits – maximum or minimum levels which ensure safety of the product. For example, if the number of bacteria in a sample is below a certain level, then the product is deemed acceptable; if the number of bacteria is above that level, the product is deemed unacceptable. Minimum internal temperatures are critical limits for cooking

4. Monitoring and sampling – the systems and procedures used in food production must be monitored to make sure they are being followed. Samples are taken at each step so they can be tested to see whether the critical limits have been breached.

5. Corrective action – if the monitoring and sampling indicates an unacceptable level, then the processes and procedures must be adjusted to prevent it happening again.

6. Verification – all businesses must make sure that their HACCP procedures are working correctly. There is a variety of procedures that can be followed to verify the accuracy of the HACCP program

7. Record keeping – all testing, monitoring and verification must be recorded and those records must be stored. This is so you can prove that your procedures meet the requirements.

3. Hygiene Standards for: a. Persons who handle and prepare foodstuffs Personal hygiene includes all aspects of hygiene related to your person. It includes your body, clothes, jewellery and the way you handle and care for these things with relation to contaminants.

When handling food constantly, it is extremely important to have high levels of personal hygiene:

Shower daily

Shave (if required) and wash your hair

Do not touch your hair during work

Use shampoo and conditioner for cleaner, healthier hair

Brush your hair prior to service to look neat and professional

Tie back long hair or cover it with a hairnet or hat

Never brush your hair in a food area

Do not wear makeup or jewellery in the kitchen. Food items can get stuck

under jewellery and let bacteria grow, which can contaminate other food.

Makeup can stain your uniform and contaminate food

Keep your nails short and clean, as dirt and bacteria can thrive under them

Nail polish is not to be worn by food handlers, as it can chip and contaminate

food. Artificial nails can fall off into food without you realising

Cuts, abrasions and open sores harbour bacteria and bodily fluid and must be

prevented from coming into contact with food. This also prevents bacteria from food entering the wound and causing infection. Bright waterproof dressings can be detected easily if they come off. You may want to wear gloves as added protection.

b. Premises Good hygiene assists a business as it helps minimise waste. For example, if food is stored correctly it will last longer and less will need to be discarded. Clean kitchens will harbour fewer pests and bacteria, which means less contamination and reduced waste. Keeping equipment well-cleaned and maintained also assists in lowering maintenance and replacement costs, as it lasts longer. It is also important to remember that hygiene is a legal requirement and noncompliance can cost the business a great deal in fines or even result in closure. Because of this, many large establishments employ independent food auditors to regularly inspect premises, conduct audits and take food samples for further testing by laboratories.

c. Equipment It is important to identify and report any maintenance or equipment cleaning needs that you cannot immediately handle yourself. All equipment must be included in the

cleaning schedule so that it is cleaned periodically. However, some equipment may need to be cleaned between the regular cleanings, especially if it is used often, or for messy tasks. If equipment is broken or does not meet food safety requirements for some reason, it must be taken out of use and repaired as quickly as possible.

d. Cross-contamination risks in the 3 areas mentioned in a,b,c: Cross-contamination is one of the most frequent causes of food poisoning, yet it is easily preventable. A typical example of cross-contamination is when raw chicken is handled and the juices are then transferred to lettuce. The bacteria transferred to the lettuce do not get cooked, so they are allowed to multiply and are then ingested by the customer. This is easy to prevent:

Colour-coded chopping boards will mean that a different board is used for the

chicken and lettuce

Washing your hands between tasks means that you will not transfer the

bacteria

Wearing gloves and replacing them between tasks will help prevent crosscontamination

Knives and other utensils must be cleaned and sanitised before using them for

a different item

All preparation areas and surfaces must be cleaned and sterilised between

tasks

4. Provisions for cleaning regimes including cleaning procedures, sanitation and suitable chemicals or mechanical procedures (for example a dishwasher). Every establishment should have a cleaning plan/schedule to ensure proper hygiene. Floors, walls, equipment and benches should be cleaned on a regular basis. This will prevent accumulation of dirt and also prevents pests from breeding.

Areas that require special attention are:

Fridge seals

Slicing machines (inside of blade)

Blenders (especially under the centre part of the blade)

Mincers (disassemble after use and wash thoroughly)

Once equipment has been cleaned it must be sanitised. Using commercial dishwashers can assist in kitchen hygiene, as pots, ladles and other kitchen utensils, cutlery, crockery and glasses can all be washed at the correct temperature. Make sure that the dishwasher reaches the required temperature during the wash and rinse cycle, as temperatures over 80°C will kill many harmful microorganisms. Specific student answers for chemicals and procedures may vary and should be evaluated accordingly.

5. Each step of the catering cycle from ordering to distribution of foods, with the requirements and monitoring processes at each step clearly outlined, with applied examples. (For example it is insufficient to state “measure temperature” – you will need to explain how temperatures are measured; what the specific temperature must be according to the commodity you are inspecting; and what your corrective actions will need to include in case of any discrepancy – apply these at all steps.)

Ordering – ensure that you have clear product specifications and good standards for quality, as well as delivery and hygiene procedures. Only use suppliers with appropriate accreditation, who meet food safety requirements.

Receiving – ensure that deliveries are systematically checked on arrival:

Use a data logger in transit and check the temperature of refrigerated items

Check for any signs of deterioration, such as frozen food starting to thaw

Food items should have no obvious contamination

Packaging needs to be in its original condition with each food item separated

from others

Canned foods must not have dents or protrusions

Milk products must be the normal shape, e.g. yoghurt containers are not

bloated

Ensure separation of cooked and raw foods to prevent cross-contamination

Storing – ensure food is stored according to relevant requirements:

Cold and frozen food must be stored in the appropriate storage facility at the

correct temperature, e.g. frozen food in a sealed freezer below -18°C

Keep items separated and stored according to their potential for crosscontamination,

e.g. cooked foods on the top shelf, raw foods below, all food to be covered

Keep main food groups separate in cool room, e.g. dairy, meat and vegetables

on different shelves at the appropriate temperature, i.e. below 5°C

Store dry foods in a cool, dry location, on shelves with even temperature and

good ventilation

Regularly check use-by dates and quality indicators such as freezer burn

Preparing – keep preparation of different food items separate wherever possible:

Keep raw and cooked ingredients apart and do not use the same tools or

cutting boards for different tasks

Wash, peel and rewash (WPRW) items in clean water to prevent contamination

from chemicals and bacteria. Do not store vegetables in water for extended time periods, as this affects their nutritional value

Wash all equipment and tools used for raw food prior to using them for cooked

food

Clean and sanitise benches and cutting boards in between production steps

Do not leave food in the danger zone (between 5 and 60°C) for more than 1

hour

Processing, packaging and holding – par-cooking, precooking and cook-chill:

When filleting fish or boning meat or poultry, only do small amounts at a time

to minimise bacterial growth

Return prepared goods to the correct storage conditions immediately, e.g.

seafood on drip trays covered with ice, meat separated on trays and covered, poultry trussed or cut and covered on trays

High risk items which are below 70°C, e.g. custard sauce and hollandaise, need

to be used quickly

Most pathogens are destroyed during cooking when the internal temperature

exceeds 70°C. Spores and viruses, as well as toxins, can withstand heat and will still lead to food poisoning

Packaged processed food must be in sealed sterile packaging with appropriate

labelling, such as use-by date and nutritional information

Keep storage containers sealed and prevent any physical contamination prior

to adding food

To maintain shelf life, cook-chill items have to be cooked at safe temperatures

and then chilled within specific timeframes. The food safety standards require the internal temperature of food to be reduced from 60°C to 21°C in a maximum of 2 hours and from 21°C to 5°C within a further maximum period of 4 hours. Blast chillers or freezers are used for this process in commercial situations

You need a thermometer that can be inserted into food via a probe. The

thermometer must be accurate to +/- 1°C of the actual temperature. Laser thermometers can also be used to take the surface temperature

Vacuum packaging extends the lifespan of food products, however if food

items were affected prior to packaging they will still deteriorate, so you need to check for quality indicators

Use a spoon to taste food and never double-dip. Always use a fresh, clean

spoon for each taste test. Do not dip your fingers in the sauce as this will cause contamination

Transporting – minimise any adverse effects on food:

Prevent any cross-contamination and apply general food handling principles

Transport food at the correct temperature

Ensure that frozen food remains frozen while in transit

Use a data logger to record food temperatures during transport

Do not cause any damage to packaging during transport

Check portable food storage equipment regularly for temperature compliance

Selling and displaying – minimise waste and contamination:

Prevent any cross-contamination and apply general food handling principles

Sell and display food at the correct temperature, i.e. internal temperature of

cold food below 4°C and hot food above 65°C

High risk food items must not be held or displayed for long periods

Any damaged food cannot be sold

Wash your hands thoroughly prior to handling food that will not be reheated.

Use gloves, palette knives, meat forks or tongs to minimise contamination

Separate serving utensils must be provided for each food item

Sneeze guards or other protective barriers must be placed on all display items

Food cannot be sold beyond the expiry date

Customers must be supervised and food safety maintained at all times. This is

the responsibility of staff/supervisor.

Disposing – separate and store appropriately:

Items for disposal or return must be segregated and clearly labelled. E.g. Out of

date, inferior quality, delivered in error, spoilage etc.

Food for disposal must not be resold to customers

Food for disposal must be stored under appropr...

Similar Free PDFs

Particapte IN SAFE WORK Practices

- 16 Pages

Sitxfsa 002 Assessment Tool

- 40 Pages

Guide to safe manual handling

- 17 Pages

Sitxfsa001 food handling

- 14 Pages

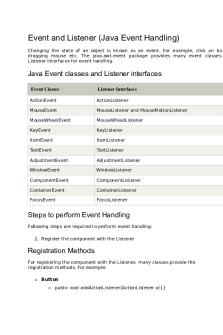

Event Handling IN JAVA

- 6 Pages

002 April in Moscow

- 11 Pages

Practices in English Notes

- 19 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu