Title Impact toughness of metallic mater PDF

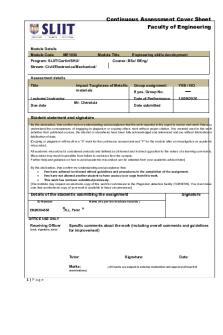

| Title | Title Impact toughness of metallic mater |

|---|---|

| Author | Anonymous User |

| Course | Materials Chemistry |

| Institution | Stanford University |

| Pages | 6 |

| File Size | 266.4 KB |

| File Type | |

| Total Downloads | 67 |

| Total Views | 130 |

Summary

Title Impact toughness of metallic mater Title Impact toughness of metallic mater Title Impact toughness of metallic mater...

Description

TITLE Impact toughness of metallic materials OBJECTIVE

To understand the metallic toughness of materials under different temperatures. To study the ductile and brittle nature of metals. To identify the toughness of a material in different engineering applications.

INTRODUCTION The impact test determines the impact toughness, which is a material property of metals, most commonly by measuring the work required to fracture a metallic specimen under impact. The impact toughness test of metals provides information on ductile-brittle nature of metallic materials upon different temperature. There are two standardized tests, namely the Charpy and Izod, were designed and used extensively to measure the impact energy. A medium carbon steel specimen with a v- notch is used to carry out this experiment. The experiment is basically done under three different temperatures, room temperature 25°C low temperature at 3°C high temperature at 150°C This experiment allows the evaluation of materials resistance to high velocity impact. In addition, if energy required to fracture notched specimens is measured as a function of temperature, an important behavior called the “Ductile to Brittle Transition Temperature” becomes evident. Materials sometimes display brittleness which prevents their use in a given design. Brittleness is characterized by fracturing with low energy under impact. The fracture energy is proportional to the area under the tensile stress-strain curve and is called the toughness.

Shiham BM (EN16066908)

THEORY Toughness is a property, which is capacity of a material to resist fracture, when subjected to impact. That is the energy absorbed during the fracture. The toughness of a material depends on following factors.

Temperature Alloying compositions Heat treatments Strengthening mechanisms

Impact Testing involves the sudden and dynamic application of the load. Parts such as shafts, bolts, anvils and dies are examples of items subjected to impact loading. The machine measures the amount of energy absorbed by the specimen for the rapture in joules unit. The amount of energy absorbed can give an indication of the toughness of a material. It can classify the different types of materials into either brittle or ductile materials. When the temperature is high the toughness of the material will be increased and when the temperature is low the toughness of the material will be lower. This is because Carbon and low alloy steels represent body-center-cubic (bcc) atomic lattices and exhibit toughness transition temperature ranges either above, at, or below room temperature depending on a number of factors. At temperatures above the transition temperature, the alloy has substantially better toughness than at lower temperatures. A notch is supplied on specimen because it ensures that the specimen will break as a result of impact load to which is subjected without notch many materials would simply bend without breaking, so it would be easier to determine their ability energy.

Shiham BM (EN16066908)

MATERIALS AND APPARATUS

Medium carbon steel specimens a with v- notch (three needed to experiment under different temperatures)

Figure 1: medium carbon steel specimen (blackscharpy.com)

Impact testing machine

Figure 2: Impact testing machine (lab-kits.com)

Oven for heating

Freezer for cooling

Shiham BM (EN16066908)

PROCEDURE Before the test Initially the specimens were prepared. Three medium carbon steel specimens were taken and a v type notch was created in all three specimens using notch cutting machine. Then one of the specimens were kept at room temperature (approximately 25’C), and the other one at a very low temperature of 34’C and the last one at very high temperature of 100’C. And then the specimens were tested using the impact testing machine one by one respectively.

During the test First, the scale of the impact testing machine was set up to zero by swinging the hammer freely. Then the specimen was placed onto the support with notch facing backside of the striking direction.

Figure 3 placing of specimen (scribd.com)

Then the pendulum was released. The pointer indicated the amount of energy consumed by the specimen for its rupture. The values were given in Joules.

After the test

The fracture surfaces of the specimens were observed and the material properties of the metal were studied.

Shiham BM (EN16066908)

CONCLUSION Toughness of a material is an important property of a material. Toughness depends on the amount of energy absorbed by the material. Therefore the toughness shows variations under different temperatures. The toughness will increase with temperature and when the temperature is low the toughness of the material will decrease. In impact test metallic samples in three different temperatures, is tested by fracturing it. And the toughness reading can be obtained using the scale in terms of joules. Temperatures can change the behavior of steel from brittle to ductile from addition of heat and from ductile to brittle by removing the heat. The amount of energy required to break a ductile material is greater than for brittle material. The percentage ductility of a fractured surface of a metal kept in 100°C is 60-65%, in room temperature is 5-9% and in -34° C it is almost 0-3 %. This shows that ductility increases with the temperature. And this concludes that the ductile – brittle nature varies upon temperature. In engineering applications these material and mechanical properties such as (toughness, brittleness, ductility) etc. are important under different conditions to obtain an effective engineering design or a structure.

Reference Anon., n.d. [Online]. Anon., n.d. NDT Resource Centre. [Online] Available at: https://www.ndeed.org/EducationResources/CommunityCollege/Materials/Mechanical/ImpactToughness.htm Hearn, E. J., 1998. Mechanics of Materials. London: B&H. Pytel, A., 2014. Mechanical Properties of Materials. New York: McGraw Hill. Ryan Carmichael, Anne Krikorian, 2008. Impact Laboratory, s.l.: s.n. William D. Callister, J. D. G. R., 2010. MATERIALS SCIENCE AND ENGINEERING. Eighth Edition ed. s.l.:WILEY.

Wikipedia Google Images Shiham BM (EN16066908)

Shiham BM (EN16066908)...

Similar Free PDFs

Indefeasibility of title

- 7 Pages

Title: PROPERTIES OF FLUID

- 11 Pages

Retention OF Title

- 4 Pages

Impact of a jet

- 6 Pages

Mental Toughness Podcast

- 3 Pages

Dura Mater and Dural Folds

- 2 Pages

OR mater - very useful

- 113 Pages

LRA- example of title register

- 4 Pages

Title The Synthesis of Alum

- 2 Pages

Ionic and Metallic Bonding

- 3 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu