MAR3203 UCF Fall18 Exam4 Check Progress PDF

| Title | MAR3203 UCF Fall18 Exam4 Check Progress |

|---|---|

| Course | Marketing |

| Institution | University of Central Florida |

| Pages | 9 |

| File Size | 509.8 KB |

| File Type | |

| Total Downloads | 74 |

| Total Views | 181 |

Summary

Download MAR3203 UCF Fall18 Exam4 Check Progress PDF

Description

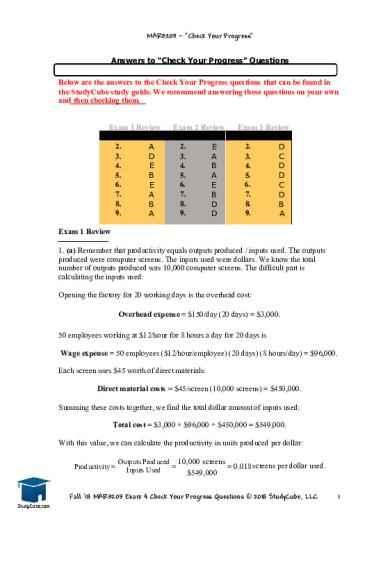

MAR3203 – “Check Your Progress” Answers to “Check Your Progress” Questions Below are the answers to the Check Your Progress questions that can be found in the StudyCube study guide. We recommend answering these questions on your own and then checking them.

Exam 1 Review 1. A 2. A 3. D 4. E 5. B 6. E 7. A 8. B 9. A

Exam 2 Review 1. B 2. E 3. A 4. B 5. A 6. E 7. B 8. D 9. D

Exam 3 Review 1. C 2. D 3. C 4. D 5. D 6. C 7. D 8. B 9. A

Exam 1 Review 1. (a) Remember that productivity equals outputs produced / inputs used. The outputs produced were computer screens. The inputs used were dollars. We know the total number of outputs produced was 10,000 computer screens. The difficult part is calculating the inputs used: Opening the factory for 20 working days is the overhead cost: Overhead expense = $150/day (20 days) = $3,000. 50 employees working at $12/hour for 8 hours a day for 20 days is Wage expense = 50 employees ($12/hour/employee) (20 days) (8 hours/day) = $96,000. Each screen uses $45 worth of direct materials: Direct material costs = $45/screen (10,000 screens) = $450,000. Summing these costs together, we find the total dollar amount of inputs used: Total cost = $3,000 + $96,000 + $450,000 = $549,000. With this value, we can calculate the productivity in units produced per dollar: Productivity

Outputs Produced 10,000 screens 0.018 screens per dollar used. Inputs Used $549, 000

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

1

MAR3203 – “Check Your Progress” 2. (a) The fewer months that are averaged in, the more volatile the forecast will be. Therefore, the 2-month moving average forecast will have the most volatile results. Below is a graph depicting a 2- and 5-month moving average forecast:

3. (d) The best performing model will be the one that has the best accuracy. The more accurate a model is, the lower its forecast error will be. Because the MAD, MSE, and MAPE measure forecast error, the better models will have lower values. Since Model D has the lowest MAD, MSE, and MAPE values compared to all of the models, it performs the best. 4. (e) Remember that the seasonal index for Semester 1 is equal to the average of the seasonal indices for each period corresponding to Semester 1: periods 1, 3, and 5. To calculate the season index for each of these periods, divide the actual demand by the forecasted demand. For period 1, the seasonal index is equal to 1,000 / 855.44 = 1.17. For period 3, the seasonal index equals 980 / 748.58 = 1.31. For period 5, the seasonal index is 920 / 641.73 = 1.43. The seasonal index for Semester 1 is the average of each of these indices: Seasonal index =

(1.17 1.31 1.43) 1.30. 3

5. (b) The service level critical fraction is equal to Service Level =

Cu , (Cu Co )

where Cu is the cost of underage and Co is the cost of overage. Rachel’s underage cost is equal to the profit from a single muffin: $3.50 - $1.50 = $2.00. Her overage cost is calculated as the cost/unit – salvage value = $1.50 - $1.00 = $0.50. Using this information, we can calculate her desired service level. Service level =

$2.00 0.8 80%. ($2.00 $0.50)

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

2

MAR3203 – “Check Your Progress” 6. (e) To find the total cost to order and carry the inventory per year, we need to use the formula TC

Q D H S. Q 2

We are given all of these values except Q, the economic order quantity. We find Q using the equation Q=

2 DS H

2(100)($7) 27 units. $2

Now we can find the total cost: TC

27 100 ($2) ($7) $52.93 . 2 27

7. (a) This is a reorder point problem. Because we are given known values for daily demand and lead time, we can use the simple formula ROP = d * L + SS. Since SS is equal to one day’s supply, SS = 50 cupcakes. Solving for the ROP, ROP = 50 cupcakes / day * 8 days + 50 = 450 cupcakes. Therefore, the business should reorder more cupcakes when its stock reaches 450 cupcakes. 8. (b) The safety stock equation when lead time is constant and demand is variable is SS = z(service level)*σd ( L ), where z is the z-value associated with her desired service level, σd is the standard deviation in demand, and L is the lead time. Since demand and lead time are given in days, we do not need to convert any units. The standard deviation in demand is 25 and L is three days. The z-value associated with a 90% service level is approximately 1.28. Plugging this information into the equation, SS = 1.28*25 ( 3) 55.43. Therefore, Polly will want to keep 56 lollipops in safety stock.

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

3

MAR3203 – “Check Your Progress” 9. (a) Remember that manufacturing is concerned with the production of tangible goods. Healthcare has many of the important qualities that you can recognize as being characteristic of a service: intangible product, high labor investment, consumption and production occur at the same time, and high consumer contact. Exam 2 Review 1. (b) The process strategy associated with low variety and high volume is product focus. The product focus is common for products with high, stable demand and low variety. This is called a product focus because facilities are organized by product. Examples include oil refineries, sugar processing plants, and glass manufacturing facilities. Since these products are made in high volume with very little variation, most production processes are automated. 2. (e) Both the process focus and mass customization strategies manufacture products in high variety. 3. (a) Since June is tailoring her services to each individual client, this is an example of a process focus strategy. Remember that most services use this strategy. 4. (b) Process charts do not provide a “big picture” view for process analysis, FLOWCHARTS provide the “big picture” overview of a process. Process charts show more detail about each process and go into detail about each individual step. 5. (a) This area corresponds to products made in low quantities with a high level of variety. The process focus strategy is most appropriate. 6. (e) The critical path is the path with zero slack, or the path that takes the longest duration when summing the completion times for each activity. Activity Designation A B C D E F

Required Predecessors --A, B C C D, E

Duration (days) 2 3 4 3 4 2

Using the table above, we can go through a forward pass of the project’s path. In the forward pass, we calculate the earliest each activity can be completed. The times we use are the durations given in the table.

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

4

MAR3203 – “Check Your Progress” 0

7

2

10

D

A 3

7

11

C 0

13

F 7

3

11

E

B

Notice how C cannot start until after 3 days have passed because it depends on the completion of B. Even though A is finished after 2 days, B still has 1 more day to go. The same occurrence happens with F; F must wait on E to finish even though D is done by 10 days. Let’s now carry out a backward pass. When carrying out the backward pass, we’re thinking about the latest time an activity can start without delaying the project. 0

2

7

A 1

10

D 3

3

7

8

11

7

7

11

11

C 0

3

3

F

B 0

13

11

E 3

7

13

11

Because E must start by 7 days in order for the project to not be delayed, C must be finished by 7 days. If C is finished any later than 7 days, the entire project will be delayed. Now that we have these early and late starts and finishes calculated, we can determine the slack time for each activity. For this solution we will use LS – ES to find the slack: Activity Designation A B C D E F

Duration (days) 2 3 4 3 4 2

Slack (LS – ES) 1 0 0 1 0 0

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

5

MAR3203 – “Check Your Progress” Because activities A and D have slack, they are not on the critical path. Therefore, the critical path is B-C-E-F: 0

2

7

10

D

A 1

3

0

3

3

7

8

11

7

7

11

11

C 3

F

7

3

13

11

E

B 0

13

11

7. (b) We determine the expected time of the project by summing the durations of activities on the critical path. In the previous question, we calculated the critical path to be B-C-E-F. Therefore, the expected project time is ETproject = 3 + 4 + 4 + 2 = 13 days. 8. (d) Based on the chart, we can construct the following network diagram: 3

7

B 0

3

10

14

3

3

9

A 0

9

14

9

9 9

14

14

20

13 FINISH

F 10

20

E

D

C 3

14

14

Remember that the critical path is the path with zero slack, or the longest path in the project. To find the critical path, let’s sum the activity completion times for each of the activity paths in the project. A B E = 3 + 4 + 6 = 13 weeks. A C D E = 3 + 6 + 5 + 6 = 20 weeks. A C F = 3 + 6 + 4 = 13 weeks. Just because two of the paths have the same duration, A C F and A B E, does not mean there are two critical paths in the project. The total duration of the project is the

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

6

MAR3203 – “Check Your Progress” longest duration, calculated as 20 weeks. The only activities that have slack in this project are Activity B and Activity F. Remember that the slack is calculated as the LS – ES. For Activity B, slack time = 10 – 3 = 7 weeks and the slack for Activity F = 10 – 9 = 1. This means that Activity B can be delayed up to 7 weeks without delaying the project and Activity F can be delayed up to 1 week. The only answer choice that is false is that the project has more than one critical path. 9. (d) Project planning involves establishing a project’s objectives and creating a work breakdown structure, a project deliverable that divides a project into smaller components to organize the team’s work. Exam 3 Review 1. (c) We are asked to determine if the central tendency of the process has assignable variation. To do this, we must establish the upper and lower control limits for the process with respect to the mean weight and see if any sample means fall outside of these limits. The upper and lower control limits for the central tendency of a process are given as follows:

UCL x x A2 R and

LCLx x A2 R .

To use these formulas, we need to find x and R :

x

1 1 x i (24.3 24.0 23.8 24.1 24.1) 24.06 k i 5

and R

1 1 Ri (0.2 0.1 0.4 0.3 0.1) 0.22 . k i 5

Using the control chart factor table, A2 = 0.37 for samples containing 8 observations. Plugging these values into the formulas, we find the limits are

UCLx 24.06 0.37(0.22) 24.14oz. and

LCLx 24.06 0.37(0.22) 23.98 oz. If any of our sample means fall outside of this range (23.98 oz. to 24.14 oz.), the process has assignable variation with respect to the mean weight. We see Sample 1’s mean of 24.3 oz. is greater than the upper control limit and Sample 3’s mean of 23.8 is less than

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

7

MAR3203 – “Check Your Progress”

the lower control limit. Therefore, this process does have assignable variation with respect to its central tendency. 2. (d) Some of the tactics companies can use to maintain lean inventory, or little inventory, are:

Reduce lot sizes Implement pull production systems Develop JIT delivery systems Use group technology Improve throughput, or production speed Reduce setup time

A company wants to REDUCE lot sizes, not increase them. Lot sizes are the quantity increment in which a company is able to purchase materials from its supplier. For example, if Toyota’s tires supplier mandates that tires be sold in quantities of 100, the lot size is 100 tires. Large lot sizes require manufacturers to hold large amounts of works-inprogress goods and raw materials in inventory. 3. (c) Since the volume of liquid is MEASURABLE DATA, we must either use an X-bar chart or an R chart. Since the factory is interested in controlling the mean amount of liquid in each 2 L bottle, we should use an X-bar chart to ensure that the mean amount of liquid in each of our samples is under control (the means do not deviate far from 2 L and remain within the control limits). An R chart would be more effective if we were interested in controlling the dispersion of the volume of liquid in each bottle (the process distribution). 4. (d) The 5S’s of lean operations are:

Sort – Only keep what is needed in the workplace. Set in order (Straighten) – Reduce waste and improve work flow. Shine (Sweep) – Clean the workplace every day. Standardize – Eliminate process variation by employing standard procedures. Self-discipline (Sustain) – Frequently review processes to maintain progress.

5. (d) A business should seek to prevent problems rather than inspect its products to find them. Therefore, it is best to invest in preventative measures so that there are as few errors as possible in a process. This means that a business’s preventative costs should be greater than these other costs that occur after the product is made. 6. (c) The plan, do, check, act cycle pertains to continuous improvement. Organizations should strive to plan an improvement strategy, test the plan, evaluate its effectiveness, and implement the strategy, documenting its progress.

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

8

MAR3203 – “Check Your Progress”

7. (d) The various times are measured data. Therefore, an X-bar chart must be used to determine the upper and lower control limits for the central tendency. To create an X-bar chart, you must know the x and R values. x equals the sum of the means divided by the total number of samples:

x

42 53 48 47 50 49 48.17. 6

R equals the sum of the ranges divided by the number of samples: R

3.57 5.94 3.52 5.78 5.82 3.59 4.70. 6

To find the upper limit, use the formula

UCLx x A2 R . Referring to the control chart factor table, A2 for n = 6 is 0.48. Therefore,

UCL x = 48.17 + 0.48(4.70) = 50.43. To find the lower control limit, use the formula

LCLx x A2 R = 48.17 – 0.48(4.70) = 45.91. 8. (b) If a sample falls outside the upper or lower control limit, the process is out of control. The lower limit is 45.91 and the upper limit is 50.43. Because there are multiple samples outside of this range, this central tendency process is considered to be out of control. Assignable (non-random) variation has a certain cause that can be fixed. If a sample statistic falls outside the lower and upper limits, the variation is deemed nonrandom and corrective action should be taken to fix this process. Because this process is out of control, there is assignable variation. 9. (a) Waiting/queues is the category of waste that encompasses machines and operators, as well as inventory, that are idle.

Fall ‘18 MAR3203 Exam 4 Check Your Progress Questions © 2018 StudyCube, LLC

9...

Similar Free PDFs

SCS 200 Progress Check 1

- 2 Pages

Progress check one scs 200

- 1 Pages

Atasoy ACCT3526 fall18 sec401

- 7 Pages

Awong CPSY706 Fall18 - Outline

- 9 Pages

Popular Institutions

- Tinajero National High School - Annex

- Politeknik Caltex Riau

- Yokohama City University

- SGT University

- University of Al-Qadisiyah

- Divine Word College of Vigan

- Techniek College Rotterdam

- Universidade de Santiago

- Universiti Teknologi MARA Cawangan Johor Kampus Pasir Gudang

- Poltekkes Kemenkes Yogyakarta

- Baguio City National High School

- Colegio san marcos

- preparatoria uno

- Centro de Bachillerato Tecnológico Industrial y de Servicios No. 107

- Dalian Maritime University

- Quang Trung Secondary School

- Colegio Tecnológico en Informática

- Corporación Regional de Educación Superior

- Grupo CEDVA

- Dar Al Uloom University

- Centro de Estudios Preuniversitarios de la Universidad Nacional de Ingeniería

- 上智大学

- Aakash International School, Nuna Majara

- San Felipe Neri Catholic School

- Kang Chiao International School - New Taipei City

- Misamis Occidental National High School

- Institución Educativa Escuela Normal Juan Ladrilleros

- Kolehiyo ng Pantukan

- Batanes State College

- Instituto Continental

- Sekolah Menengah Kejuruan Kesehatan Kaltara (Tarakan)

- Colegio de La Inmaculada Concepcion - Cebu